3D Printing VS Injection Molding for Elastic Parts

Whether it is life, or industrial production, are full of a large number of elastic parts, such as soles, rubber bands, mouse wrist guards, industrial washers and so on.

At present, the main processes for manufacturing elastic parts are injection molding and 3D printing.

So if there is a need to make flexible parts, which process is better to choose?

After comparing their advantages and disadvantages, you will know!

01 Injection molding process

Commonly used materials: silica gel, TPE, TPU

Advantage

1, quickly complete mass production;

2, high precision parts, good material performance;

3, when the number of parts reaches a certain amount, the unit cost is low.

Disadvantage

1, Mold cost is high;

2, The shape has certain limitations.

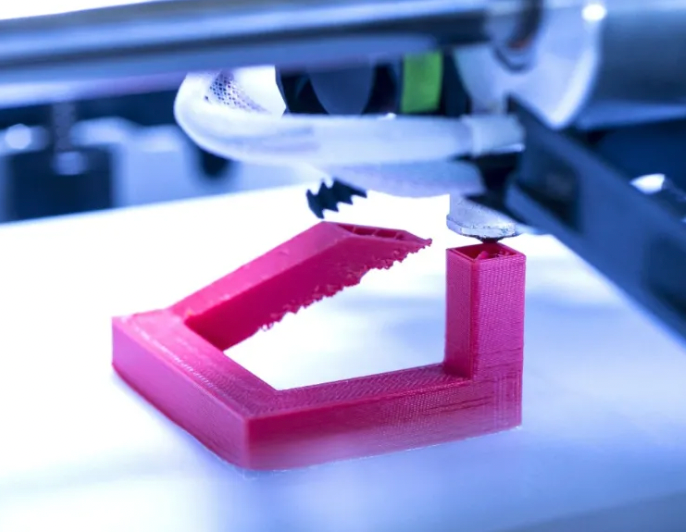

02 3D Printing

Commonly used is the FDM process, the material is made into wire, sent to the nozzle of the 3D printer, heated and extruded, layer upon layer superimposed molding.

Common materials: TPE, TPU

Advantage

1, Small batch manufacturing, the single cost is low;

2, The molding limit is small, can make complex modeling;

3, No need to make expensive molds.

Disadvantage

1, Accuracy and details are not as good as injection molding;

2, The mass production speed is slow;

In SUMMARY:

After the comparison, according to the advantages and disadvantages of the two processes to make a summary, mass production, the use of injection molding process; 3D printing can be used for single piece or small batch production.

Welcome to contact us via enquiry@abcrapid.com to get more information !

Search

Recent Post