To Find a Suitable Method to Manufacture Aluminum Prototypes

Aluminum is the most commonly used material in prototype production. Compared with other metal materials, aluminum has strong plasticity and good production performance, so it has a very good advantage in production. Industries ranging from aerospace to medical to automotive require durable mechanical and structural components, and aluminum is ideal for this. On the one hand, it is ductile and can be made into lightweight alloys with many metal elements and can be processed into different shapes of aluminum. On the other hand, the aluminum profile relative to other metal materials, no metal pollution, no toxicity, surface oxide layer no volatile metals, is a benign metal material can be recycled.

Manufacturers can use different techniques to create aluminum prototypes. Depending on the part, quantity or geometry and product structure, they can choose to use metal 3D printing, CNC machining, aluminum die casting, extrusion or sheet metal fabrication. Therefore, how to choose a suitable method to manufacture aluminum prototypes?

Computer Numerical Control machining is one of the most common machining methods. Using the numerical control machine tool, this method can produce the prototype very accurately in the shortest time, so that the prototype can obtain a high precision. In addition, this method is convenient to produce products, only according to the customer's CAD drawings can be programmed to produce products. Of course, numerical control machining also has certain limitations. Numerical control work is a process of subtraction, so it will produce a certain amount of material loss; And the cost of CNC processing is higher, the product cost is higher. If you want a high precision aluminum prototype and have enough cost, CNC Machining is a good choice.

Sheet metal manufacturing is a group of processes that involve bending, cutting and assembling aluminum sheets. It is often used to make functional prototypes, such as shells and industrial parts. The raw materials used in them are thin aluminum alloy sheets, such as 5052. Sheet metal manufacturing typically involves laser cutting, punching, bending and welding. In order to maintain quality, it is beneficial to use the same sheet metal technique in the prototyping and production process, so that the quality of the products produced in large quantities can be consistent. Ideal for mass production of the same part. Of course, sheet metal manufacturing has its limitations. If multiple technologies are required, it can be more expensive than other processes. For example, a single part may require a laser cutting machine and a punching machine, while a CNC machining requires only one machine.

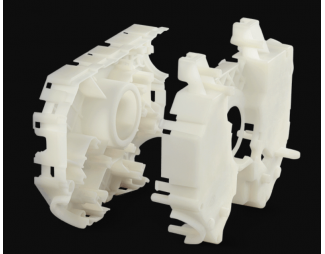

As for these other methods like aluminum die casting, metal 3d printing or extrusion, each processing method has its own unique advantages, but also has certain limitations. Metal 3D printing is a very popular processing method in recent years. Unlike CNC, it is an additive manufacturing method, which means that it is built layer by layer. Most are suitable for structurally complex designs and can be printed directly using their geometric flexibility. And aluminum die casting and extrusion, are a kind of larger processing methods, need mass production manufacturing is more economic, for small batch products, the cost of opening the mold is huge and uneconomic.

Summary, compare to above several methods, we know that CNC Machining is the best way to manufacture aluminum prototypes. Welcome to contact us via enquiry@abcrapid.com to get more information!

Search

Recent Post