How to Save Machining Cost When CNC Clear Prototypes?

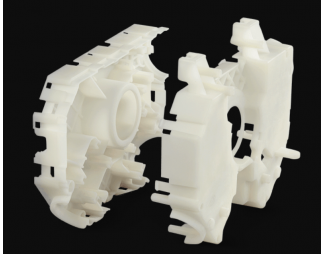

General speaking, the most common method that used to produce clear prototypes is CNC Machining. Also, there are two other methods that can produce clear parts, such as vacuum casting and 3D Printing. The two methods both have their pros and cons, today we take cnc machining as a important point to see how to save cost.

In order to make clear prototypes, now there are only two materials can be used, one is polycarbonate, the other is acrylic. The original block of polucarbonate and acrylic are transparent. Meanwhile, the process is limited to CNC Machining when use the two materials. Of course, plastic injection molding can produce high-quality transparent parts, but the intial cost of mold is extremely high because the transparent parts require high quality steel mold, like NAK-80, sometimes costing millions of dollars. In addition, the turnaround time will be very long. Therefore, it is not wise to use injection molding to make small batch prototypes. If the quantities are large, injectiom molding would be more economic. Summary, if you want to save machining cost, the first way you should do carefully evaluation and choose the suitable manufacturing method.

We know that CNC Machining is a subtractive machining process, its principle is to take a piece of raw material, cut off the unnecessary material, and shape of the part we want. But the raw block clear mateials of pc and acrylic are standard materials that have a certain wall thickness or height. In the case of the same thickness and the same raw material particles, the transmittance of acrylic sheet is 2-3% higher than that of PC, which is close to 90%, which is not easy to distinguish with the naked eye. After the surface of these clear plastic has been machined, the whole part would look quite foggy and coarse. In order to make it clear, manual sanding and polishing will have to be applied. And polycarbonate parts require a special method to get clear effect, it is vapor polish.

Manual sand and polish is a quite time-consuming labor-intensive job, espcecially when there are some scratches or imperfections on surface, it will take more longer time, which creased the cost of parts. To polish machined surface is more difficult than the original surface of materials. Therefore, we need to take into consideration of the thickness of height when we evaluate each parts. When confronted with designs that are close to standard raw materials, if the thickness (height) of the part does not have a strict tolerance or thickness is not important, we recommend not machining the surface to save machining costs (sometimes in considerable quantities).

Above are two ways to save machining cost when CNC clear prototypes. If you have more effective ways to save cost for suggesting or you want to make clear prototypes, welcome to contact us via email enquiry@abcrapid.com for more clear information.

Search

Recent Post