Introduction Serveral Surface Finishing Types of CNC Machined Pa

A good prototype product, from production to molding to the final product, need to go through many processes. And products that look great are usually the result of multiple surface finishes or post-treatments. Generally for the rapid manufacturing industry, surface processing is often used in the post-processing way. Surface processing refers to the formation of a surface layer with one or more special properties on the surface of a material by physical or chemical means. Surface finishing can improve the appearance of parts, wear resistance, corrosion resistance, hardness, strength and other characteristics. Next, we will introduce several common types of surface treatment used in CNC machining.

1.Polishing

Polishing is a surface finishing method that uses mechanical, chemical, or electrochemical action to reduce the surface roughness of a part in order to abtain a flat and bright surface. There are two types of polish class, one is N6 polish, the other is N8 polish. The N8 polish even can get the similar effective of mirro polish.

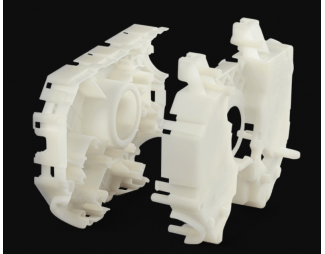

2.As machined

As the name implies, it refers to the parts keep the original machined pattern surface after having been finished from the machine, no other process. It is one of the common surface finishing in CNC Machining. The surface roughness of Ra 0.2 to Ra 3.2. Surface finishes such as deburring and sharp edges are usually applied.

3.Anodized

Anodic oxidation is the electrochemical oxidation of metals or alloys to form an oxide film on the surface of parts. It can not only prevent the wear and oxidation of parts, but also increase the aesthetic effect. Most importantly, it can achieve different colors on the surface of parts, and this kind of surface finishing is only applicable to metal parts, plastic parts cannot be oxidized.

4.Bead blasting

Sand blasting is in the sandblasting machine, using the impact of high-speed sand flow, the surface of the parts for cleaning and grinding, so that the surface of the parts to obtain a certain degree of cleanliness and roughness. The type of sandblasting can be selected, the most commonly used sand is fine sand. This kind of sand has less impact on the parts and does not cause too much deformation. General parts after sandblasting will have a slight deformation, the thinner the product wall thickness of the product is easier to deformation. For parts with strict tolerance requirements, sandblasting is not recommended.

5.Brushing

Brushing is a physical surface processing method, it is the use of machines to uniformly pull out a layer of linear surface texture, so as to achieve a decorative effect. Generally, drawing is suitable for aluminum products, and aluminum products need to be oxidized again after drawing to protect the product surface from air corrosion.

Above are some some types of surface finishing in CNC Machining works, if you are interested in these methods, welcome to contact us via enquiry@abcrapid.com!

Search

Recent Post