Applications and Uses of Vacuum Casting

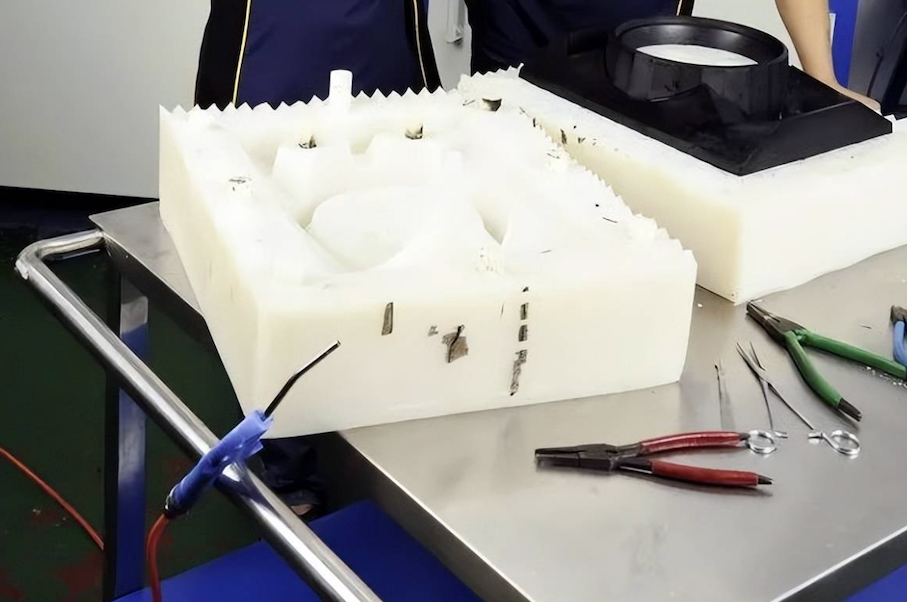

Vacuum casting is a versatile process that has several uses in various sectors. The process’s capacity to produce complex and precise components renders it an excellent option for high-quality outcomes.

Aerospace Components:

Precise aerospace components can be manufactured using this method. Vacuum casting is commonly used to make components like air ducts, fuel systems, and even certain parts of airplane exteriors because of its greater precision, reproducibility, and ability to generate exquisite detail.

Medical Implants:

In the medical business, vacuum casting is commonly utilized to produce complicated parts and components. It is suitable for the fabrication of implants and prostheses.

Automotive Industry:

Automotive parts are frequently created using vacuum casting due to the process’s ability to produce highly detailed components. The greater accuracy and repeatability of silicone vacuum casting can help automobile parts, including intake manifolds, exhaust systems, and body panels.

Food Business:

The process is frequently used to produce complex pieces for the food business. It can produce molds, packaging components, and other complicated forms required in food production.

Consumer Goods:

Vacuum casting can produce complicated consumer products such as toys and sporting equipment. The method may produce very accurate parts suitable for consumer usage.

If you have any Vacuum Casting project please feel free to contact: enquiry@abcrapid.com.

Search

Recent Post