Current problems and solutions in the medical device prototyping

Any technology will gradually develop some disadvantages with the development and progress of the times. When the medical device prototype was first successfully developed, it was still a representative of new technology. It freed people from busy labor and greatly improved the efficiency and quality of model production. However, there are currently some problems. So, what are the current problems with medical device prototype production technology? How to solve them?

Problems:

1. Material utilization efficiency is not high

Traditional medical device prototype technology has a low utilization rate of raw materials. Compared with current 3D printing technology, there is a gap. 3D printing technology can use all raw materials without waste.

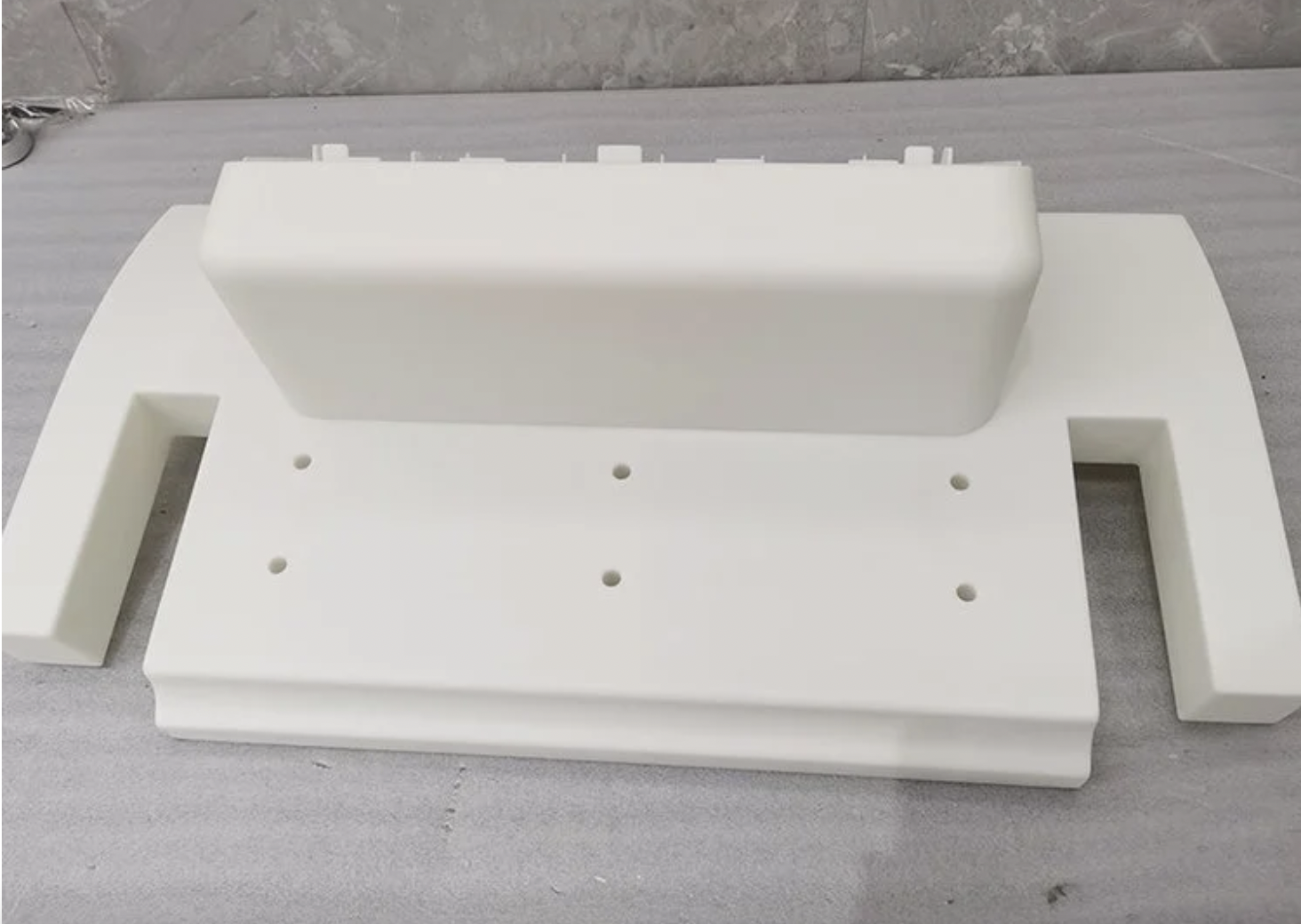

2. The workload of processing complex parts is large

Medical device prototyping technology can only process some simple-shaped prototyping models, but it is unable to deal with some internally complex models. If you want to make complex parts, you need to go through multiple molding processes, and you need to separate and program each molding step, which is a very heavy workload.

3. Fixture design should be considered

When making part models, the design of the fixture needs to be considered, but there are many technologies that do not require the fixture to be considered when making models.

After knowing the problems existing in Shanghai's medical device prototype model technology, we must pay attention to some details during the processing process to avoid the existence and occurrence of problems.

1. Plan production procedures to improve material utilization and work efficiency.

Before we use medical device prototype technology to produce models, we must understand the processing content, and reasonably arrange the installation surfaces and processing base surfaces according to the processing content, so that we can achieve a reasonable purchase of raw materials and improve the utilization rate of materials. While reducing waste, it also improves the production efficiency of medical device prototype processing technology.

2. Pay attention to the thermal deformation produced during multiple molding processes.

When making complex parts, although we need to go through multiple molding techniques, in order to obtain exquisite parts, we must pay attention to the deformation caused by heat during the processing, and we must be careful during the production and installation process. Dimensions of parts.

If you have some parts to make, please feel free to contact us via enquiry@abcrapid.com to get fee quote.

Search

Recent Post