How to Improve The Machining Accuracy of CNC Prototype

In the process of CNC hand model proofing, some hand models have very high requirements for machining accuracy, so how can the hand model factory improve the machining accuracy of CNC prototypes? To improve the accuracy of CNC hand model processing, we must first understand the factors related to accuracy.

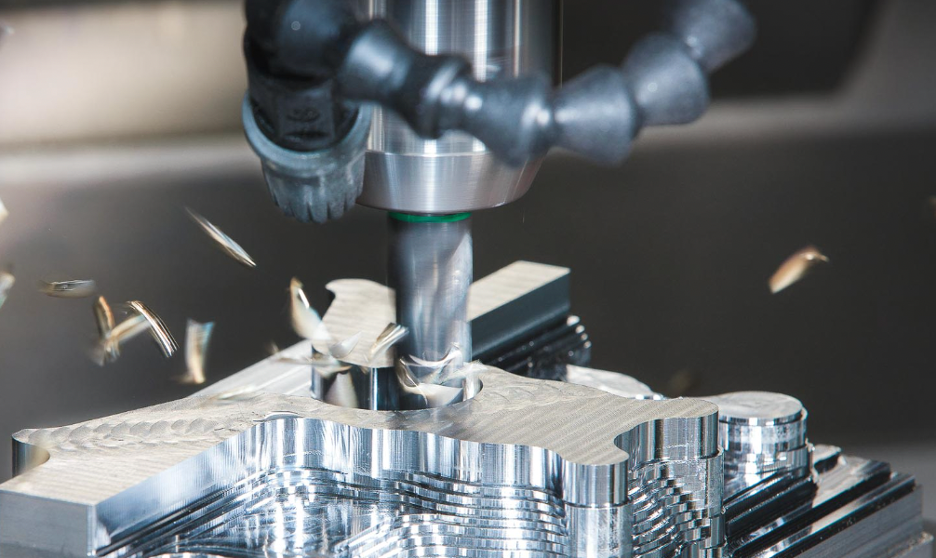

1. Select the appropriate processing tool and tool holder structure

The rational use and selection of cutting tools will be an important factor affecting the quality of CNC machining. In high-speed machining, coated carbide will replace most front-end steel tools, including simple tools such as reamers, ball-end cutters, and boring tools, and is used in most conventional machining fields. In rough machining, we usually choose large diameter tools for machining. In order to save costs and reduce the difficulty of tool manufacturing, we will use machine-clamped carbide inserts to remove chips as much as possible for rough machining; high speed is used for semi-finishing. High-speed feeding of the insert tool makes the semi-finishing process faster; in the finishing process, try to use high-precision round-head mirror inserts on the carbide tool holder to ensure the strength of the tool and tool holder for correct machining processing. While maintaining precision, it saves the cost of choosing an all-alloy tool. In processing, we also need to pay attention to the fillet radius of the inner contour on the finished part must be greater than or equal to the tool radius. Use a tool with a radius smaller than the corner fillet radius for circular or oblique interpolation. Processing, which can avoid the overcut phenomenon caused by linear interpolation and ensure the quality of mold finishing. In processing, we also need to pay attention to the fillet radius of the inner contour on the finished part must be greater than or equal to the tool radius. Use a tool with a radius smaller than the corner fillet radius for circular or oblique interpolation. Processing, which can avoid the overcut phenomenon caused by linear interpolation and ensure the quality of mold finishing. In processing, we also need to pay attention to the fillet radius of the inner contour on the finished part must be greater than or equal to the tool radius. Use a tool with a radius smaller than the corner fillet radius for circular or oblique interpolation. Processing, which can avoid the overcut phenomenon caused by linear interpolation and ensure the quality of mold finishing.

2. Reasonable CNC processing scheme

In high-speed and high-precision machining, the design importance of NC process scheme has been mentioned to a higher position. The entire machining process must be controlled. Any mistakes will seriously affect the quality of the mold, so the process plan will affect the processing quality. play a decisive role. CNC machining process design can be regarded as the state control of the system process plan from the blank of the part to the machining of the part.

A good process plan is more difficult in the whole design process, and can only be obtained through continuous practical summary and modification. The amount of information to be considered in the design process is large, and the relationship between information is extremely intricate, so programming must be used to ensure the actual work experience of designers. Therefore, the design quality of the process plan mainly depends on the experience and level of the technicians.

3. Scientific management and maintenance

The positioning accuracy of CNC machine tools is an important precision that is different from ordinary machine tools. Together with the geometric accuracy of the machine tool, it has an important influence on the cutting accuracy of the machine tool, especially the hole distance error in hole machining. CNC machine tools can judge their processing accuracy according to their achievable positioning accuracy, so detecting and compensating the positioning accuracy of CNC machine tools is a necessary way to ensure processing quality. In addition, due to wear and tear, with the gradual increase of the kinematic pair clearance, the reverse deviation will also increase. Therefore, it is necessary to regularly measure and compensate the reverse deviation of each coordinate axis of the machine tool.

4. Adopt better CNC processing equipment

In CNC processing, the processing accuracy of the mold is related to the equipment, the better the processing equipment, the higher the processing accuracy. So choosing better CNC equipment is the most direct way. In order to meet the customer's demand for higher machining accuracy, all CNC equipment was replaced with better CNC equipment, and the highest precision of 0.02mm was achieved on the hardware.

Welcome to contact us via enquiry@abcrapid.com to get more information !

Search

Recent Post