How Vacuum Casting Works ?

Nov 14 , 2025 | Blog

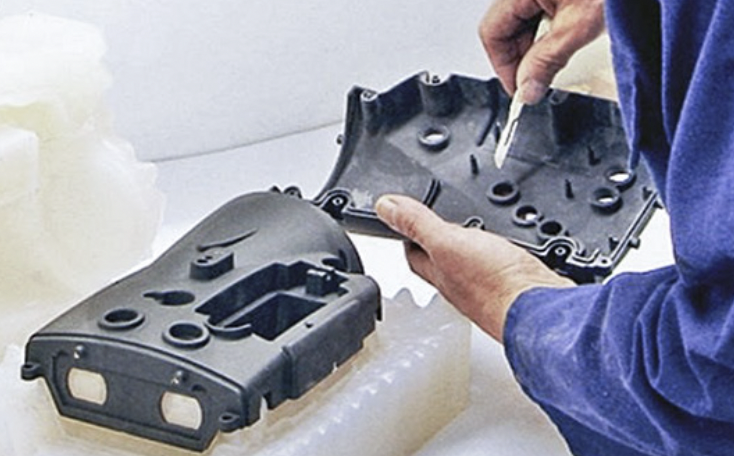

Vacuum casting uses a silicone mold and a vacuum chamber to create detailed plastic or rubber parts with smooth surfaces and minimal defects

Here’s a step-by-step breakdown of the process:

1. Create a 3D Model

As with most modern manufacturing processes, the first step is to design a 3D model of the part.

Use CAD software such as AutoCAD, SolidWorks, or CATIA.

To get optimal results, follow injection molding design rules, including draft angles, uniform wall thickness, and allowances for undercuts.

2. Build the Master Pattern

Produce a master pattern from the 3D model using SLA 3D printing or CNC machining.

While CNC was traditionally used, it still offers higher dimensional accuracy, especially for pre-series parts.

3D printing speeds up prototyping and reduces cost during early design validation.

3. Create the Silicone Mold

Place the master pattern in a casting box along with any cores, inserts, and gating systems.

Pour liquid silicone over the pattern to capture its geometry and surface details.

Cure the mold in an oven at 40°C for 8 to 16 hours, depending on its size.

Once cured, cut the mold open along the parting line to reveal the negative cavity.

Apply a mold-release agent to prevent sticking and avoid surface flaws.

4. Mix and Pour the Resin

Prepare a two-component polyurethane resin and add any required pigments.

Preheat the mixture to ~40°C for better flow.

Install the mold in the vacuum chamber and connect the pouring gates.

Mix and deaerate the resin under vacuum for 50–60 seconds to remove air bubbles.

Apply vacuum to the mold so gravity fills the cavity evenly without trapped air.

5. Demold the Parts

Cure the filled mold in an oven for 1 to 4 hours, depending on the material.

After curing, remove the hardened part from the mold, then trim gates and perform any needed finishing.

A single silicone mold typically produces 10 to 20 parts, depending on the geometry and resin used.

Illustration of the vacuum casting process

Search

Recent Post

CNC Machining Services China For Global Industries

11 - Feb - 2026

China CNC Machining Service Suppliers Lead Global Manufacturing

13 - Jan - 2026

The Advantages Of CNC Turning Parts

01 - Dec - 2025

Custom CNC Online Precision Cutting Service

01 - Dec - 2025

What type of manufacturing is machining?

21 - Nov - 2025

How much does it cost to get something CNC machined?

21 - Nov - 2025

Other New Articles

Jul 01 , 2021 | Blog

Jul 06 , 2021 | Blog

Jul 13 , 2021 | Blog