Metal Material For CNC Machining

Metal materials are the most commonly used CNC machining material for different CNC machined components. These CNC metals offer good mechanical properties, including high strength, thermal resistance, electrical conductivity, and hardness. Below are common CNC machining metals:

Aluminum

Aluminum is a highly machinable metal with diverse applications. Besides, it is one of the most common CNC materials and a better alternative to metals like titanium and steel. Aluminum and its alloys are amongst the most commonly used materials. Aluminum alloys exhibit excellent strength-to-weight ratio, corrosion resistance, low weight, and eye-catching silvery appearance.

Although aluminum has different grades, not all are suitable for making CNC-machined parts and components. However, 6061 and 7075 aluminum grades are the strongest aluminum alloys. They exhibit high machinability,making them ideal CNC machining materials for fabricating low-weight machined parts, such as aerospace frames, aircraft components, and automotive engine components.

7075 can be hardened to T6. 7075 T6 aluminum is suitable for fabricating plastic injection mold tools, automotive and aerospace frames, and high-strength recreational equipment for mountain climbing. Furthermore, most machinable aluminum materials are used in healthcare, consumer electronics, construction, and architecture.

Carbon Steel and Its Alloys

Carbon steel and its alloys are ideal for diverse applications because of their higher machinability and superior strength. Carbon steel alloys are primarily compatible with different heat treatment procedures. Hence, they exhibit improved mechanical properties. Unlike most CNC metals, carbon steel material is not too expensive. Medium carbon steel is strong and suitable for heavy-duty applications like shafts, bolts, and studs.

Notably, the unattractive appearance of carbon steel makes the material incompatible with aesthetic applications. Similarly, carbon steel, mild steel, and its alloys are not intrinsically corrosion-resistant CNC materials. Although alloy steels are more corrosion-resistant and ductile than carbon, carbon steel is stronger. Nevertheless, these materials remain ideal for several industrial and manufacturing applications regardless of their limitations. They offer improved durability, machinability, and accessibility. Steel and its alloys are widely used in CNC machining structural components such as beams and mechanical fasteners.

Copper and Its Alloys

Copper CNC Machined Part

Copperis a popular CNC machining material with unique properties, including outstanding electrical and thermal conductivity. Since it exhibits excellent conductivity, product engineers consider copper and its alloy an ideal choice for electrical and electronic components. Similarly, copper alloys are perfect CNC materials for jewelry making due to their exceptional aesthetic appeal. Electrical wire, jewelry production, and magnetic devices are typical applications of copper.

Brass, bronze, and copper are indispensable CNC machining materials. Brass and bronze are common copper alloys with unique characteristics. Brass comprises of copper and zinc. It is a very soft metal and can be machined without lubrication. It exhibits excellent electrical conductivity, corrosion resistance, and machinability. Manufacturers often use brass for applications that don’t require great strength, such as fabricating low-strength fasteners, electrical equipment, consumer goods, and plumbing equipment.

On the other hand, bronze comprises copper, tin, and other compounding elements. It is strong, durable, and highly resistant to corrosion. Bronze exhibits excellent machinability, making it ideal for machining precise components like bearings and gears. Moreover, adding aluminum and phosphorous can increase the impact resistance, toughness, and strength of bronze.

Stainless Steel

Stainless Steel CNC Machined Parts

Stainless Steel is another widely used CNC metal with a glossy appearance. It has excellent strength, toughness, corrosion, and wear resistance. Alloy steel is reasonably priced and available in different grades. However, it exhibits high hardness, making it one of the most complex CNC materials to machine. Stainless steels contain chromium, which allows them to deter oxidation.

316 SS is one of the standard stainless steel grades with outstanding heat and corrosion resistance. Hence, it is often applicable in fabricating medical equipment, outdoor enclosures, and components used in the marine. 303, 304, and 316 stainless steel are other common CNC machined stainless steel grades used in fabricating fasteners like bushings, screws, bolts, etc.

However, manufacturers often add sulfur to 303 SS to make it more machinable. 303 stainless steel is suitable for machining nuts, bolts, shafts, gear, and fittings. Meanwhile, 304 stainless steel is readily machinable and can be welded. It is ideal for machining kitchen accessories, cutlery, architecture, and automotive components.

Magnesium

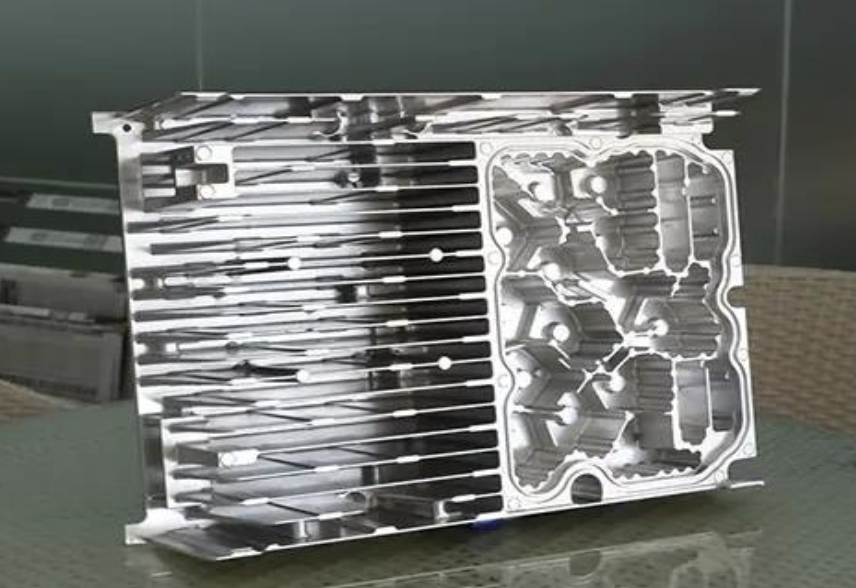

Magnesium Alloy CNC Machined Part

Magnesium is a versatile CNC machining metal with great strength and low-weight properties. Due to its excellent thermal properties, magnesium is an ideal metal for high-temperature components like engines. Furthermore, its light weight allows the manufacturing of lightweight and fuel-efficient vehicles. Magnesium is compatible with pressure die casting. Manufacturers use magnesium AZ31 for lightweight and high-strength applications such as camera frames, power tools housing, and laptop cases.

However, it is important to note that magnesium exhibits lower corrosion resistance than metals like aluminum. Also, magnesium machining is highly flammable and can be costly to process. Manufacturers often anodize magnesium machined parts to enhance their corrosion resistance.

Titanium

Titanium CNC Turned Parts

This CNC metal is incredibly strong and lightweight and offers a great strength-to-weight ratio. Its corrosion resistance property, heat conductivity, and biocompatibility make titanium compatible with CNC machining in the biomedical industry. Titanium is compatible with welding, passivation, and anodizing processes for enhanced appearance and increased protection. Although titanium possesses poor electricity conductivity, it exhibits good heat conductivity and a high melting point.

Furthermore, titanium is ideal for fabricating high-performance machined parts for the medical, military, aerospace, and automotive industries. More notably, titanium is suitable for making cutting tools for CNC machines.

If you have any metal prototyping project, please feel free to contact : enquiry@abcrapid.com.

Search

Recent Post