The different between Electroplating and Painting

Electroplating and Painting are two common surface treatment processes that have significant differences in principle, materials, effects and applications. Here are the main differences:

1. Different principles

Electroplating:

• Using the principle of electrolysis, under the action of direct current, the metal ions are reduced from the electrolyte and deposited on the surface of the part to be plated (cathode) to form a layer of metal coating.

• requires electrification, which is an electrochemical process.

Painting:

• The paint is atomized by the spray gun so that it is uniformly attached to the surface of the object to form a paint film.

• Does not require electricity, is a physical process.

2. Different materials

Electroplating:

• Use metal salt solution (such as nickel salt, chromium salt, copper salt, etc.) as the electrolyte.

• The coating material is usually metal (such as nickel, chromium, zinc, gold, silver, etc.).

Painting:

• Use various types of paint, including water-based paint, oil-based paint, powder paint, etc.

• The paint film material is an organic polymer.

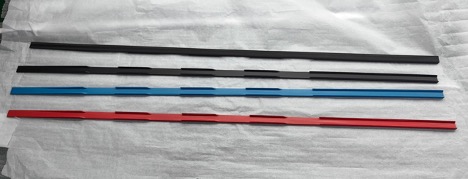

3. Different results

Electroplating:

• coating has metallic luster, high hardness, good wear resistance and corrosion resistance.

• can significantly improve the appearance quality and functionality of parts (such as electrical conductivity, reflectivity).

• Color options are limited, usually metallic (e.g., silver, gold).

Painting:

• Paint film rich color, decorative, can achieve a variety of visual effects (such as matte, light, texture, etc.).

• protection is better, but the hardness and wear resistance are usually not as good as electroplating.

4. Different Cost

Electroplating:

•Higher costs, especially for parts that require special processes (such as gold plating, silver plating) or complex shapes.

•Professional electroplating equipment and wastewater treatment facilities are required.

Painting:

• Relatively low cost, suitable for mass production.

• High quality spray painting or complex processes such as multi-layer spraying can also add to the cost.

5. Different application scenarios

Electroplating:

• Commonly used in parts requiring high wear resistance, corrosion resistance or electrical conductivity, such as automotive wheels, hardware, electronic components, jewelry, etc.

Painting:

• Often used for objects requiring rich colors and decorative effects, such as car bodies, furniture, home appliance shells, toys, etc.

6. Environmental protection

Electroplating:

• The electroplating process will produce waste water, waste gas and waste residue, which requires strict environmental protection treatment.

Painting:

• Volatile organic compounds (VOCs) may be produced during the spray painting process, but water-based paints and powder paints are more environmentally friendly.

Sum up

Electroplating: Suitable for scenarios that require metallic texture, high wear resistance and corrosion resistance, but at a higher cost.

Painting: suitable for scenes requiring rich colors and decorative effects, lower cost, but less hardness and wear resistance.

According to the specific needs (such as functionality, appearance requirements, budget, etc.), the appropriate process can be selected. Any projects please feel free to contact: enquiry@abcrapid.com.

Search

Recent Post