The Main Process Of CNC Prototype Production

The Main Process Of CNC Prototype Production:

There are many ways of Rapid Prototyping, such as CNC Machining, 3D printing, silicone mold, metal sheet, injection molding. The process of each molding method is different, and what I share in this article is the main process of CNC molding. Hope to help you all!

1, CNC programming: programming is the first step of the hand plate model production, the first step of the engineer to get the drawings will first review the drawings, according to the product process production is convenient, CNC processing whether the need for disassembly processing to program, to ensure that the appearance of the product is not affected. Then write CNC engraving and milling path according to the processing method, set the type of tool and processing speed according to the material characteristics, and finally write CNC engraving and milling path and engraving and milling speed according to the equipment performance.

2, CNC machining: the programmer program sent to the CNC machining center, the operator according to the program single selection of the corresponding materials, tools for product processing.

3, Manual processing: after CNC machining down, the surface will have a lot of burrs, these machines are unavoidable, so it needs to be manually disposed of, there are congenital defects in CNC machining, the right Angle area can not be fully processed in place, which also requires manual cleaning with specific tools, and then assembly.

4, Grinding and polishing: the surface of CNC machining products will leave knife marks, and the appearance of each hand plate needs to be polished by hand. After getting the product, the polishing master will first check the 3D drawing file, analyze the appearance of the product, and reflect the edges, lines, gaps and so on.

5, Printing: The biggest advantage of CNC hand board is that its surface effect is closer to the final mass production effect. According to the color palette or PANTON number provided by the customer, the sprayed products are put into the oven for baking. The baking time varies according to the characteristics of materials and paints. UV can not only play a role in protecting and strengthening, but also beautify the effect of paint, the general surface treatment in addition to spray painting also includes electroplating, screen printing, radium carving, oxidation and other ways.

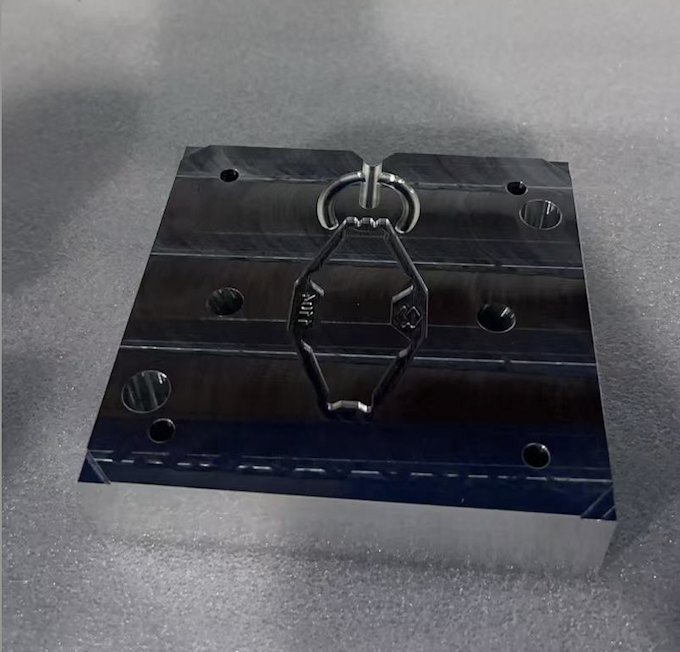

6, Finished product assembly: whether it is the appearance of the hand board or the structure of the hand board is the need to be assembled, the first is to check whether the product accessories are complete, and then carefully control the 3D drawings and process instructions provided by the customer for assembly, paying special attention to the assembly relationship and the gap between the parts.

7, Quality inspection: all the hand before shipment must be quality inspection, of course, quality inspection is not only in the last link, the quality of the hand is mainly controlled in the front of each link, so as to ensure that the product delivery on time and let customers receive satisfactory products.

If you have project in hand, please feel free to contact: enquiry@abcrapid.com.

Search

Recent Post