3D Printing/CNC Machining/Vacuum Casting Used In Different Scene

Model or part sample, small batch there are many ways to implement, which is more suitable for the customer? Shortcomings of 3D printing, CNC machining and silicone vacuum casting are as follows:

CNC Machining:

Features: Material performance is good, the surface can paint, electroplating, and other processes, durable, can be collected screws.

A deficiency; Processing is difficult to clear the Angle in place, need manual programming and post-manual processing or electric spark, workload, high price and cost. The processing speed of small parts is slow

Mainly for customers: high degree requirements, high appearance requirements, strength and temperature resistance requirements, suitable for the structure of the workpiece processing is not too complex.

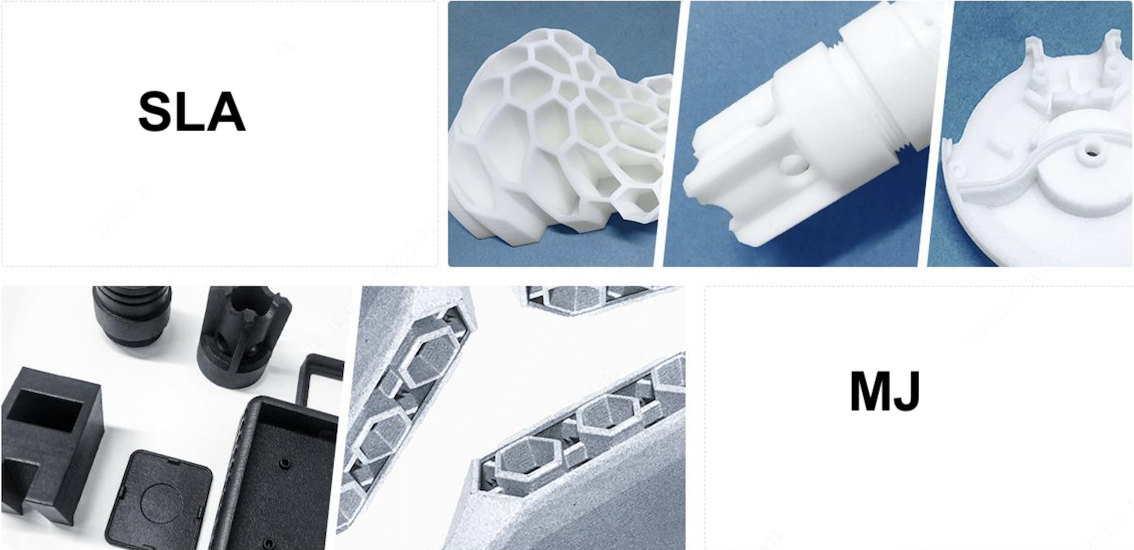

3D Printing:

Features: Strong structure, inverted, internal cross can be processed, manual processing is relatively simple. The processing speed of small parts is fast

Shortcomings: brittle, easy to break, not good bonding, oil injection effect is not very beautiful, can not be electroplated, the screw is explosive;

Suitable for making complex structure of digital products, and the appearance of the surface and strength of the small case product samples;

Metal 3D Printing:

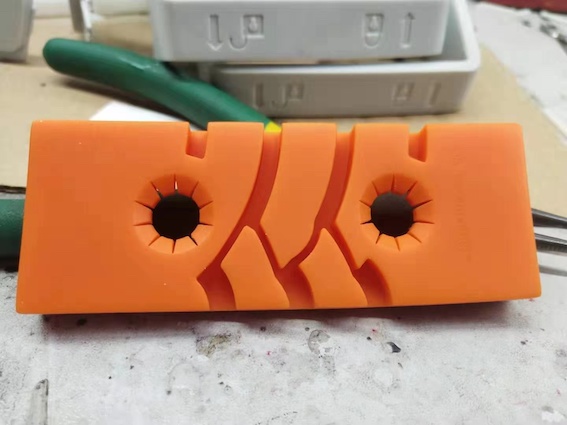

Silicone Vacuum Casting:

General material performance, surface spray effect is good, can do CNC machining and 3D printing can not do soft rubber products, can electroplating, screw collection. Viscose water,

Disadvantages: must be provided by 3D printing or CNC prototype, single set of high cost, suitable for small batch replication, replication speed, accuracy requirements are not high occasions;

Suitable for small batch products large, small and soft rubber waterproof ring have advantages;

Which products are suitable for vacuum casting:

Personalized products, small demand, more complex structure, open traditional steel mold is not cost-effective products, such as auto parts, robots, medical instruments, 3C electronic products.

Welcome to contact us via enquiry@abcrapid.com to get more information !

Search

Recent Post