Can Polypropylene be Machined?

Are you searching for reliable quality of your Polypropylene machined product? Want to maintain the quality of your product with the best mechanical properties?

Polypropylene is an eco-friendly polymer and its monomer is called as Polypylene.

Can Polypropylene be Machined?

Polypropylene can be machined by CNC machining, as it has graced as one of the most leading polymer suppliers.

Furthermore, Polypropylene is used in many industries due to its versatile properties, including automotive, commercial, medical, etc.

Moreover, DEK manufacturers are maintaining high standards by providing quality CNC Machining Polypropylene services.

Have a look at the steps of this service:

CNC Milling Services

DEK proposes accuracy in CNC milling services by keeping an eye on every character, including prototyping, mass production run, low volume fabrication, etc.

Consequently, their advanced machining workshop has an order of 3-axis, 4-axis, and 5-axis.

Furthermore, theseCNC milling machinescan create multiple complex products, including rods and machining tools that can perform with 3-dimensional axes.

Commercially, these machines facilitate contemporary cuts on the axes for fast production and modified and complex shaping.

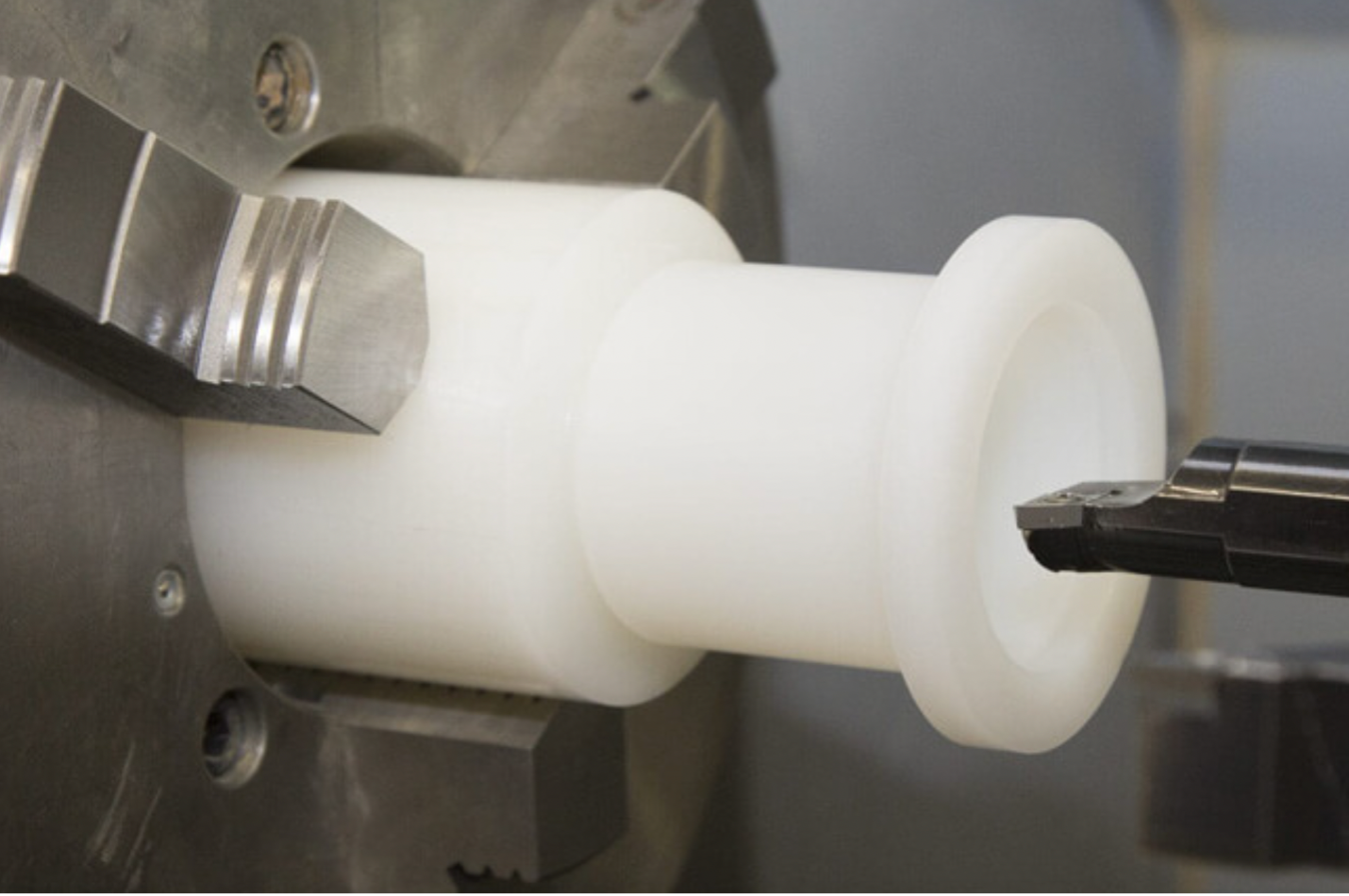

CNC Turning Services

Generally, CNC turning Services are applicable for a wide range of Polypropylene parts in various sizes.

Technically, various turning machining engines and skills make threading, boring, tapping, contour turning, etc.

Subsequently, these processes are conveniently possible and fit for high-volume manufacturing and rapid prototypes.

CNC Drilling

Commercially, CNC drilling is the best part of the CNC machining service from any machine shop.

With the help of an expert engineering team and the most advanced machines, the process can handle deep hole drilling and small hole drilling operations.

Furthermore, DEK is China’s most reliable and accurate manufacturing company due to the production of high-quality CNC machined parts.

Moreover, every step of CNC machining is performed under the supervision of an expert team and with the help of advanced machinery.

What Are the Advantages of Polypropylene Machined Parts?

The advantages ofCNC machiningPolypropylene parts are highlighted below:

Heavy Loads

Generally, CNC machining Polypropylene parts have a high tensile toughness that makes them a useful material for heavy loads, plus they have the power to resist 4800 psi.

Light-weight

Moreover, CNC machining Polypropylene parts have a low density compared to other plastics parts, so manufacturers have the privilege of saving costs from low weight.

Mechanical Strength

Technically, CNC machining Polypropylene parts are used in automotive industries and in heavy machinery that provides mechanical support to the machinery.

If you have any project please feel free to contact: enquiry@abcrapid.com.

Search

Recent Post