How Does CNC Machining Work?

CNC machining relies on computer programs to create the layout of the process in which the machine tool should function. Since users cannot directly communicate with the machine tools, Computer-Aided Design (CAD) software is used.

CAD software creates the 2-dimensional and 3-dimensional models for the required CNC machined parts. With this design, the machine knows what the final part looks like.

The computerized controls do the calculation required for removing material, so the workpiece looks like the final part created in the CAD software.

The Four Stages of CNC Machining as below:

Stage 1: Creating the CAD Model

Before CNC machining begins, the 2D or 3D model of the final design is required. This model is created in CAD software. There are many CAD software programs available online, free and paid.

Creating CAD models is not difficult and can easily be learned. However, some complex parts might require more experience with CAD, for which expert designers can be hired.

Stage 2: Converting CAD Model to CNC File

No CNC machine understands CAD language directly. CNC machines only recognize movement based on coordinates. Therefore, the CAD model must be converted to a CNC understandable file called G code.

Many CAD software programs can write the output file directly in G code by using the particular setting before saving the file.

In other cases, converting the CAD design to G code will require dedicated software called Computer Aided Manufacturing (CAM). CAM software is a very functional tool when it comes to the automation of machine processes.

Besides using CAM software, many simple free tools can convert simple CAD designs to G code with the click of a button. However, they don’t have the vast suite of features that CAM software offers.

Stage 3: Configuring the CNC Machine

Before starting manufacturing processes, the CNC machine must be set up the right way.

Think of this as configuring the printer before you print something. You need to feed the printer with pages and check specific settings. CNC machines operate similarly.

Before machining begins, there are many setup processes to complete. For instance, you must ensure the workpiece is properly positioned on the machine. The dies must also be set correctly, and other position settings.

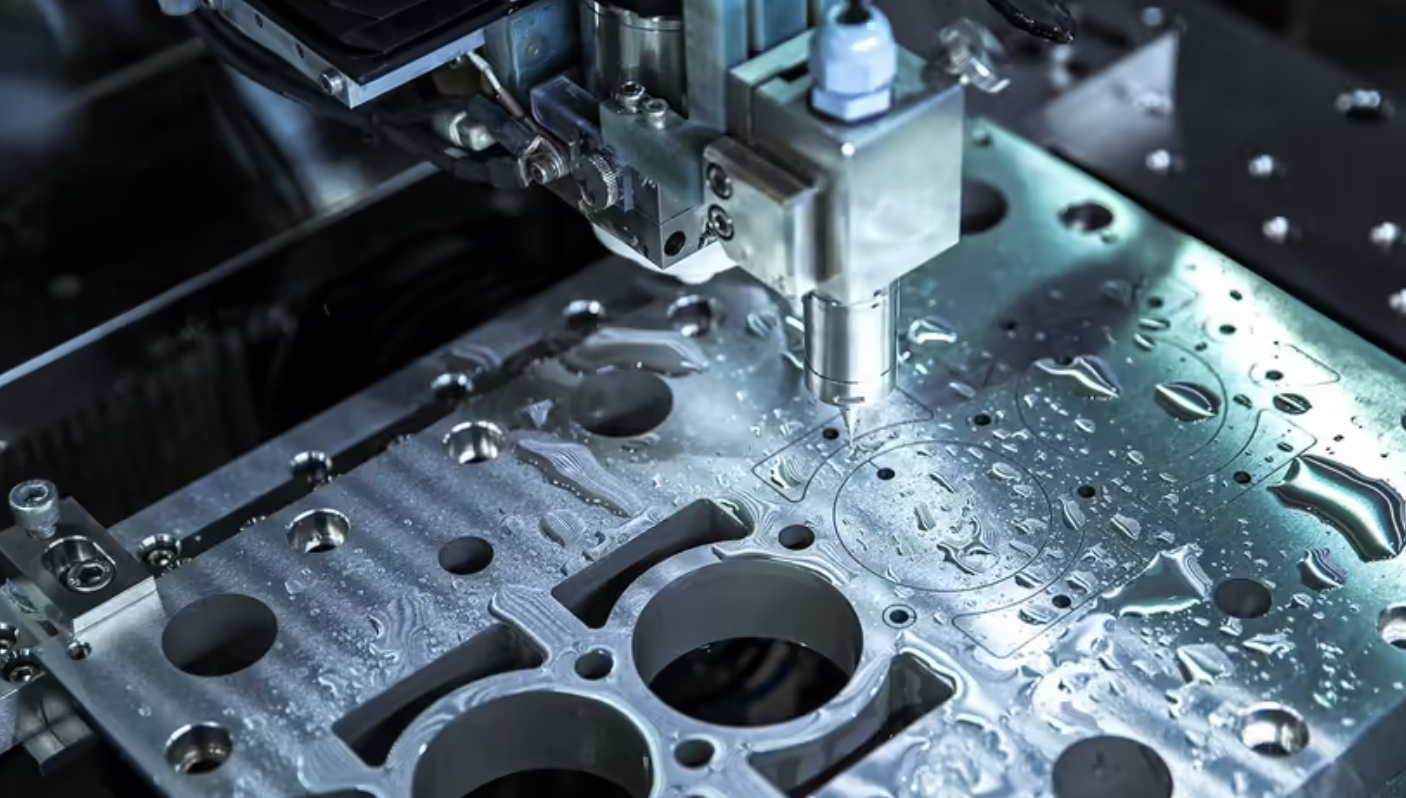

Stage 4: machining operation execution

Once the configuration stage is complete, the machine operation can begin. For this, you can execute the program on the display panel of the CNC machine.

Depending on what you design, you might have to go through various program prompts to choose different types of settings and options.

If you have some parts to make, please feel free to contact us via enquiry@abcrapid.com to get fee quote.

Search

Recent Post