How many advantages do you know of 3D printing service machines?

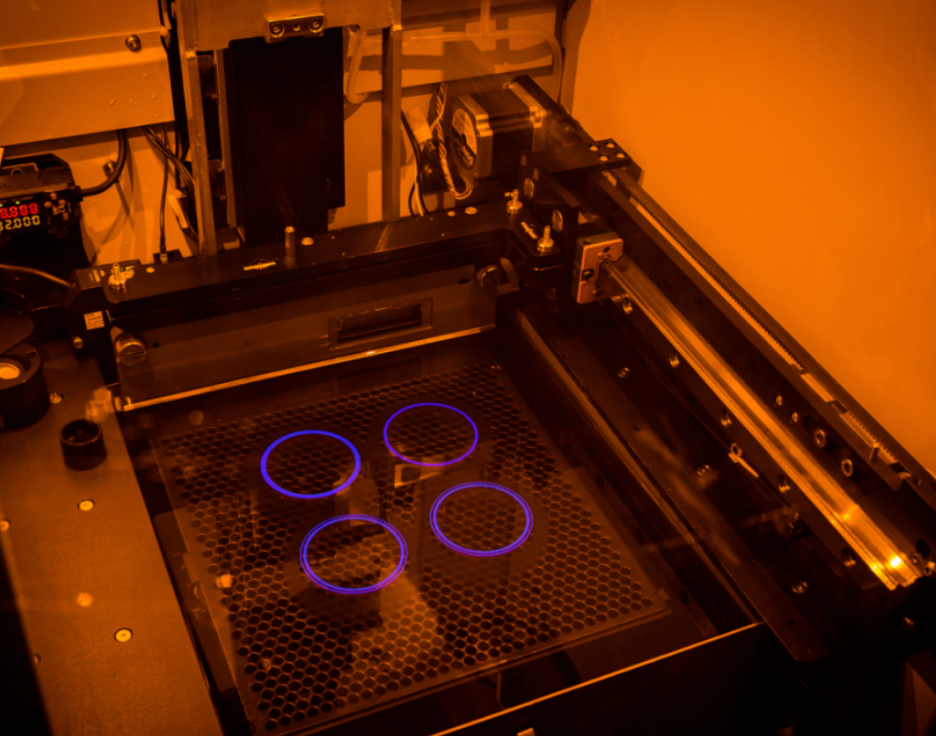

There are many methods used by 3D printing service machines, including SLA, SLM, SLS, etc. Among them, SLA is a relatively common printing technology. SLA technology, the full name of Stereo lithography Appearance, uses laser to focus light. The surface of the material is solidified so that it is solidified sequentially from point to line, and from line to surface, over and over again. In this way, the layers are superimposed to form a three-dimensional entity, which also has its unique advantages:

Advantage:

1. The light-curing molding method is an early rapid prototyping manufacturing process with high maturity and has been tested over time.

2. Prototypes are made directly from CAD digital models, with fast processing speed and short product production cycle, without the need for cutting tools and molds.

3. Can process prototypes and molds with complex structural shapes or that are difficult to form using traditional means.

4. Make CAD digital models intuitive and reduce the cost of error repair.

⒌Provide samples for experiments, which can verify and check the results of computer simulation calculations.

⒍Can be operated online and controlled remotely, which is conducive to the automation of production

Some simple assembly techniques recognized by all plastic prototyping designers, such as snap assembly, press assembly, and thread assembly, can greatly save production costs by simply and quickly assembling components. The big advantage of snap-on assembly is that no additional assembly parts are required. In the buckle design, plastic mold designers must ensure the geometric dimensions of the accessories to avoid loosening of assembly components caused by stress relaxation. Pressed assembly allows plastic components to be assembled with high strength at low cost. Threaded assembly consists of separate and combined types. Use of screws or integral screw inserts.

Aluminum alloy prototyping steel is hard and has strong firmness; metal materials such as gold, silver and titanium are all made of SLS; titanium is a material commonly used in high-end 3D printers; ABS plastic Category: ABS is a common printing material with FDM printing technology. It has many colors to choose from and can be used to print various creative home accessories or fun toys such as Lego. It is a favorite printing consumable for consumer-grade 3D printer users one.

If you have any prototyping project, please contact us to get free quote: enquiry@abcrapid.com.

Search

Recent Post