How to Adjust The Printing Speed of 3D Printing Service?

The price of plastic handboards is a few hundred yuan per kilogram for the price of these materials, which is about 40,000 yuan more expensive. Risk costs, just like nuclear reactions can be generated and can be damaged. The 3D printing technology made people see a series of hidden concerns in the early days, and the future development will also worry many people. If everything can be effectively copied, you can create what you think of, and it sounds beautiful, and it will cause us to cause thinking.

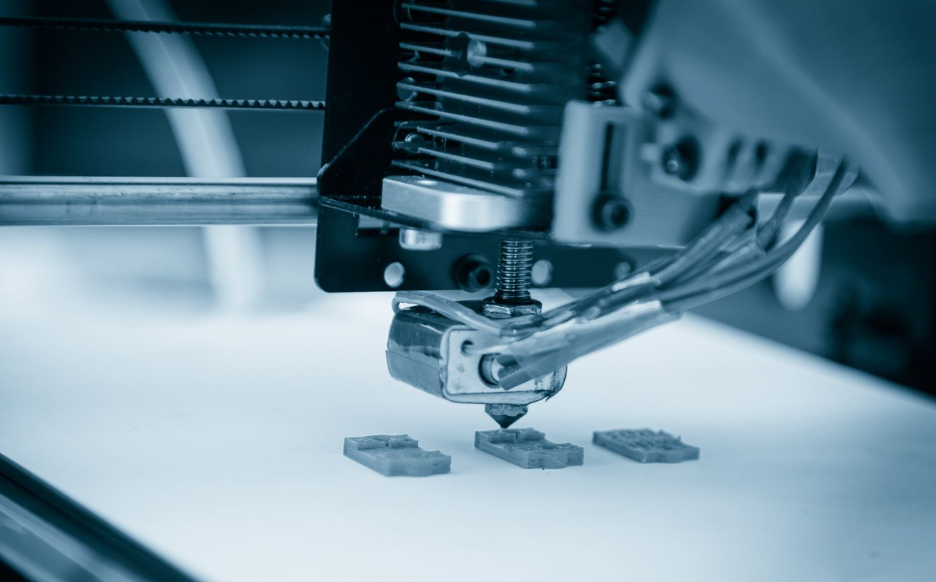

The 3D printing of aluminum alloy handboard processing is made by layer to make items. If you want to make items more fine, you need to reduce the thickness of each layer; if you want to increase the printing speed, you need to increase the thickness of the layer, which will inevitably affect the product's product. Accuracy. If the products of the same accuracy are produced, compared with traditional large -scale industrial production, there is no cost advantage, especially after considering time costs, scale costs. Industry standards, the 21st century printer manufacturer is full of flowers.

The 3D printing service see the parameterized feature modeling of the historic tree that is obtained. In one sentence, you can summarize the synchronous modeling, which vividly tells the development of CAD modeling technology. Different from traditional feature modeling, synchronous modeling is a relatively new technology. Everyone is relatively strange, but the fast and convenient brought by synchronous modeling, as well as the factor that can be edited and modified all three -dimensional model data. When you are in Solid Edge, you can easily design products with simultaneous modeling, and you will like this technology.

High print temperature: If you continuously encounter the problem of consumable wear, try to increase the extruded temperature by 5-10 degrees to make plastic easier to flow out. Click the "Print temperature" tag on the "Basic" page to set the value you want to change. Plastic is always easier to flow when the temperature is higher, so this will be a very helpful adjustment setting.

The printing speed of the 3D printing service is too fast: If the wear of consumables after the squeezing temperature is elevated, the problem of wear will continue to occur. The next thing you should do is reduce the printing speed. Therefore, because the squeezing time of the consumables becomes longer, the squeezing motor does not need to rotate so fast. The reduction of squeezing motor speed helps to avoid the problem of consumable wear. Adjust the "Print speed" of the "Basic" page, the value of "movement speed", "internal filling speed", "top/bottom print speed", "outer wall printing speed", "inner wall printing speed", etc. Try to reduce 50%to see if the wear problem disappears.

Welcome to contact us via enquiry@abcrapid.com to get more information !

Search

Recent Post