Low Volume Injection Molding

One of the challenges of creating a new product is ensuring that you get it to market as quickly as possible so that your competitors don’t beat you to it. However, you still need to make sure that it looks good and works well, or you risk investing your time, money, and reputation on a faulty product that nobody wants. Discerning manufacturers solve this conundrum, by creating prototypes of the product and relying on low volume injection molding to produce high-quality parts in small batches, so they can test and analyze the product throughout the design phase.

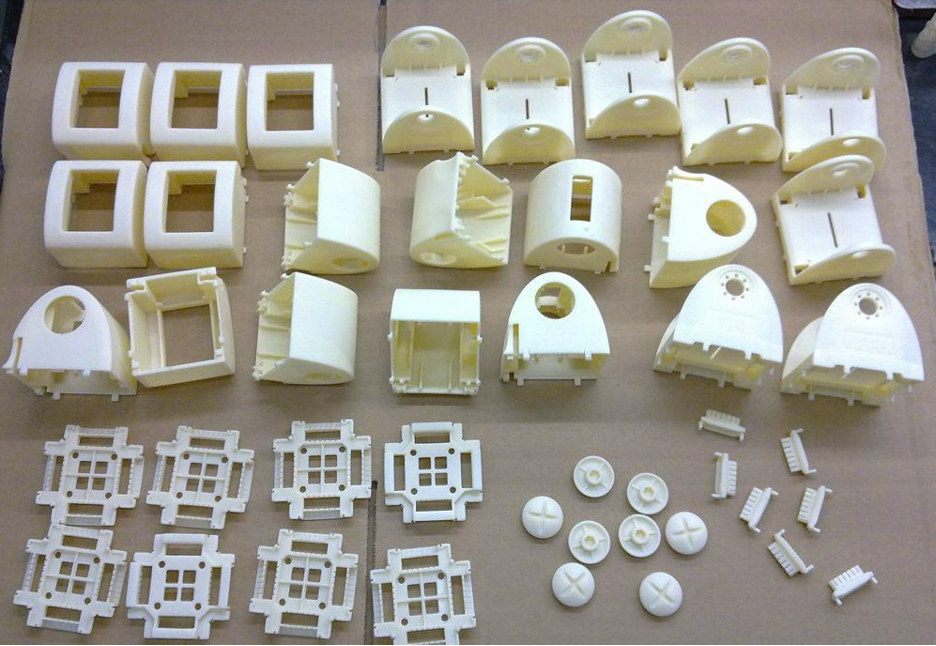

Low volume injection molding is a form of rapid prototyping or rapid tooling. Here are some of the benefits that it offers:

Low volume production – It can deliver high-quality parts of up to 100,000 in volume from production resins. This makes rapid injection molding like end-use prototype manufacturing. It still produces products that are identical to the actual production parts but reduces costs and lead times compared to actual production tooling.

Durable and functional parts – Low volume injection molding uses materials like aluminum and steel. Reputable rapid prototyping services rely on those options, particularly steel, so they can provide more value to you. Steel rapid tool injection molding can provide over double the parts that you require when compared to aluminum.

Cost-effective – This rapid prototyping method requires lower upfront costs, and it can produce actual product-grade materials, which are more practical for understanding and analyzing your final product’s design, aesthetics, and function.

Welcome to contact us via enquiry@abcrapid.com to get more information !

Search

Recent Post