Metal 3D printing

What is metal 3D printing?

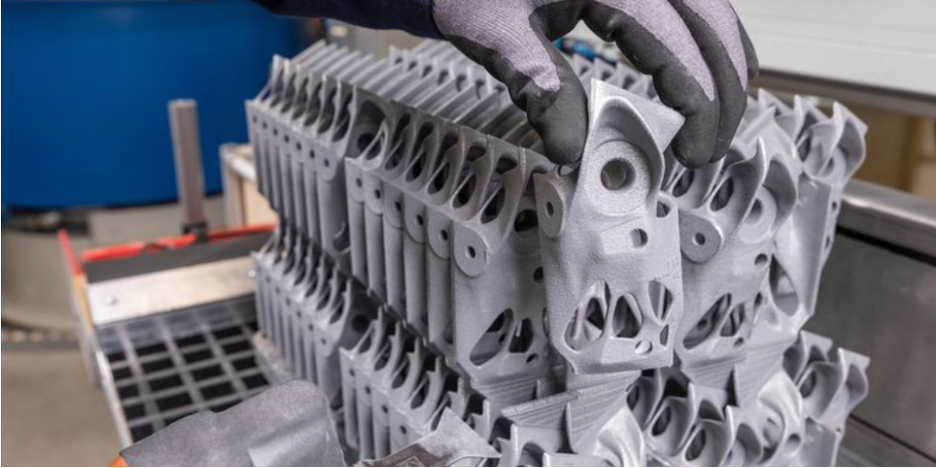

3D printing of metal, we call direct metal laser melting (DMLM) 3D printing process. This additive manufacturing process uses a high-power laser to melt and fuse successive layers of powdered metal into three-dimensional solid components. The advantage is that the more complex or feature-rich the component, the more economical the process.

The advantages of 3D printing

3D printing has many benefits, especially if you know how to optimize product design to take advantage of them. Benefits include:

1) High precision. At present, the accuracy of metal 3D printing equipment can be controlled below 0.05mm.

2) Short cycle. Metal 3D printing does not require the production process of molds, which greatly reduces the production time of models. Generally, a model can be printed in a few hours or even tens of minutes.

3) Personalization can be realized. Metal 3D printing has no limit to the number of models that can be printed, no matter one or more models can be produced at the same cost.

4) Diversity of materials. A metal 3D printing system can often realize the printing of different materials, and this variety of materials can meet the needs of different fields.

5) The cost is relatively low. While metal 3D printing systems and 3D-printed metal materials are currently expensive, they are relatively cheap to produce when used to create personalized products.

Metal 3D printing process

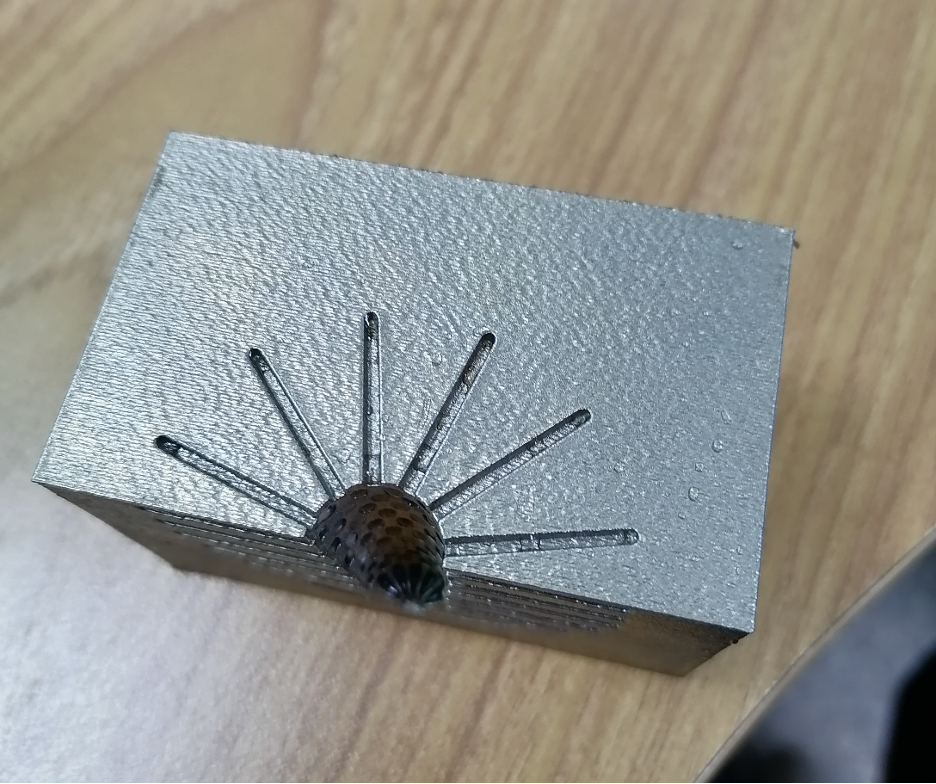

First, you must provide the 3D CAD file for your design. For best results, our engineers must review your CAD drawing files in advance and optimize the design if necessary. This can include optimizing build orientation and adding support structures to areas where gravity may cause features to distort during printing. These supports will be removed later.

We then use specialized software to cut the drawing into multiple cross-sectional layers, each representing 20-60μm thickness of the final shape. Finally, we upload the slicing file to the machine to be printed.

Metal 3D printing tolerances

The general tolerance for metal 3D printing is +/ -0.5mm. However, it depends significantly on the geometry of the part being printed. See more guidelines to follow when designing metal 3D printing.

Metal 3D printing materials

Currently, we offer 3D metal printing in titanium, stainless steel, maraging steel and aluminum. Each material has unique advantages related to mechanical properties, weight, corrosion resistance, etc. There is also an economic cost to consider, so our engineers are happy to advise you on the best materials for your application and budget.

Welcome to contact us via enquiry@abcrapid.com to get more information !

Search

Recent Post