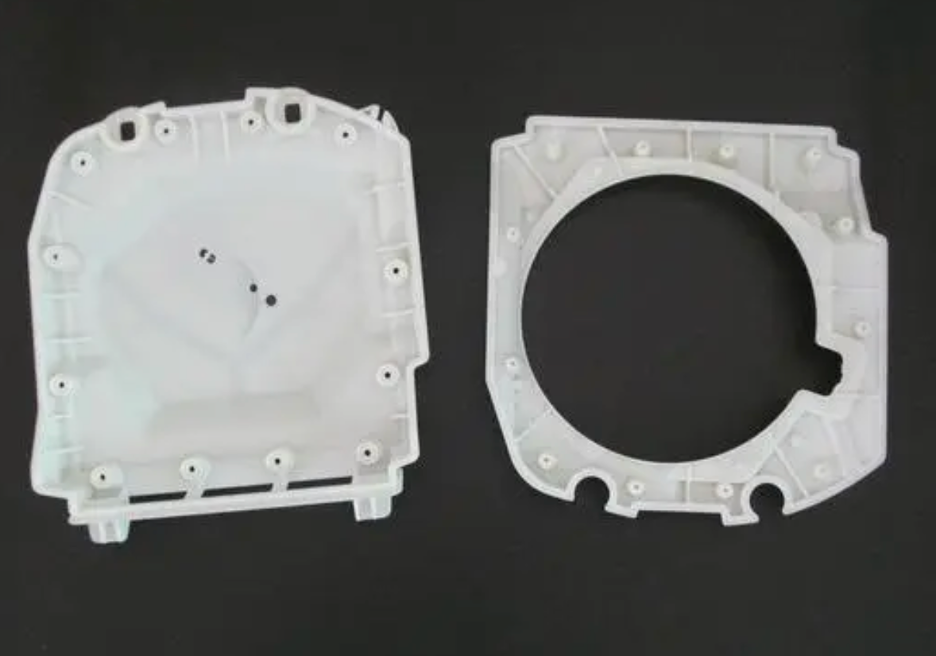

Plastic prototype production to check whether the structural des

Plastic prototypes are used to test whether the structural design is reasonable. Many products require prototype processing of various parts before production. In other words, many of them are spliced and assembled into the final product model. Therefore, the plastic prototype is first produced and processed, and then assembled to see whether each assembly is qualified, whether the clearance is up to standard, whether it is easy to install, etc. Similarly, if there are any problems, they need to be corrected, and then prototypes are made until it is finally determined to meet the requirements.

The production of plastic prototypes is all done by hand. The materials are ABS sheets, acrylic sheets, white films, etc. There are auxiliary machine tools such as milling machines, lathes, sharpeners, vacuum molding machines, etc. The master's mechanical operations and manual practice are Both carving and design abilities are required. For example, the design of the action tooth box is to design the walking, running or flying effects of the toy according to the customer's requirements, focusing on design capabilities; the simulation driver board pays attention to the master's handiwork and line feeling of the photo, and is familiar with the plastic hardware mold. Emphasis on manual carving and mold knowledge; plaster clay prototypes can be independently called handicraft sculptures.

Plastic prototypes are used to make vacuum injection molding, also known as vacuum molding, which uses prototypes to directly copy products under vacuum conditions. After the design is complete, the prototype can be obtained through various processing methods such as CNC, SLA, etc., and then the product can be obtained by copying the prototype. The copied product has high precision and good strength. It is a complete whole and fully meets the various functions of the design requirements. It is suitable for the trial production of small batches of functional parts, reducing the cost and risk of directly opening steel molds.

The accuracy of engine plastic prototype production is not only related to programming, but also to the operator. Although the performance of the machine is good or bad, when processing aluminum alloy prototypes, we can reduce errors as much as possible. Before making the plastic prototype, it is necessary to test the knife pendulum. The common method of measuring the knife pendulum is to use a calibration meter to point on the diameter of the rotating tool. The difference between the calibration meter readings is the number of swings.

If you have any prototyping project, please contact us to get free quote: enquiry@abcrapid.com.

Search

Recent Post