Rapid Injection Molding Service

Rapid injection molding is excellent option for producing large quantities of parts. The lead times and costs of it are significantly reduced compared to full production tooling.

ABC Rapid can provide cost-effective service at each stage, whether you require rapid tooling, low volume manufacturing, mass production molding making, or end-use plastic molding with tight tolerances.

Advantages of Rapid Injection Molding:

1. Lower upfront investment

2. production grade materials

3. Mass Production

4. HighSpeed

5. Flexibility

6. High quality

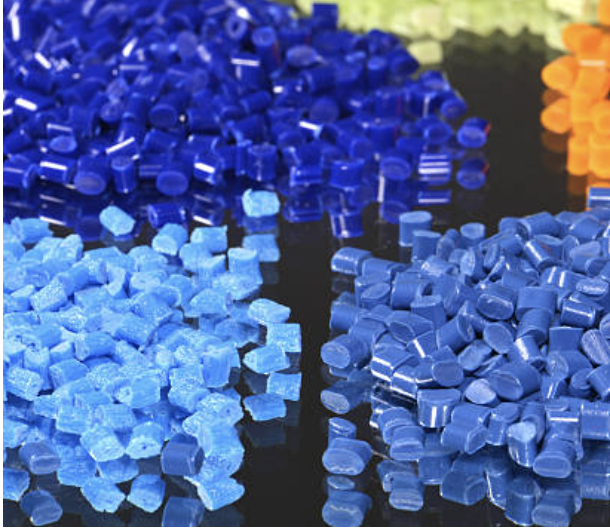

Materials of Injection Molding:

Acetal polyoxymethylene (POM)

Acrylonitrile butadiene styrene (ABS)

Nylon 66 (PA66)

Glass-filled, polyamide (PA-GF)

High-density polyethylene (HDPE)

Low-density polyethylene (LDPE)

Polybutylene terephthalate (PBT)

Polycarbonate (PC)

Glass-filled polycarbonate (PC-GF)

ABS polycarbonate (PC-ABS)

Polyethylene terephthalate (PET)

Polymethyl methacrylate (acrylic) (PMMA)

Polyphenylene sulfide (PPS)

Polypropylene (PP)

Polystyrene (PS)

Polystyrene + polyphenyl ethers (PS-PPE)

Thermoplastic elastomer (TPE)

Thermoplastic vulcanizates (TPV)

Finish Options of Injection Molding:

Pad printing

Polishing

Silk screening

Laser finishing

Custom color painting

Heat staking

Texture finishing

Welcome to contact us via enquiry@abcrapid.com to get more information !

Search

Recent Post