Rapid Prototyping Technology

Prototype technology:

When the drawing is completed or a new product design is completed, that is, before it is put on the market, the first thing you want to know is the market benefit of this product; or if you want to know whether there is a difference between the design drawing and the actual product or whether it is reasonable, etc. At this time, I suggest you first make a hand model.

In layman's terms, prototype is to make one or more models according to product design drawings or structural drawings without opening molds, so as to check the appearance or structural rationality of functional samples.

Prototype classification:

1. Manual prototype: it is mainly an early prototype, which is rarely used now, because it is mainly made by hand, and the size and appearance are difficult to meet the requirements, so this method is rarely used at present.

2. CNC prototype: It is mainly completed by CNC machine tools, so it can be divided into laser rapid prototyping (RP) prototype and CNC machining center (CNC) prototype.

Advantages of RP prototype: fast speed, mainly formed by stacking technology, so the prototype is generally rough; in addition, products with too thin wall thickness cannot be made by this method.

Advantages of CNC prototyping: precise, high-quality appearance, such as after surface spraying and silk screen printing, it is almost the same as the real product. It can be molded directly on plastic, which is more in line with product requirements, so CNC prototypes will become the mainstream of the prototype manufacturing industry.

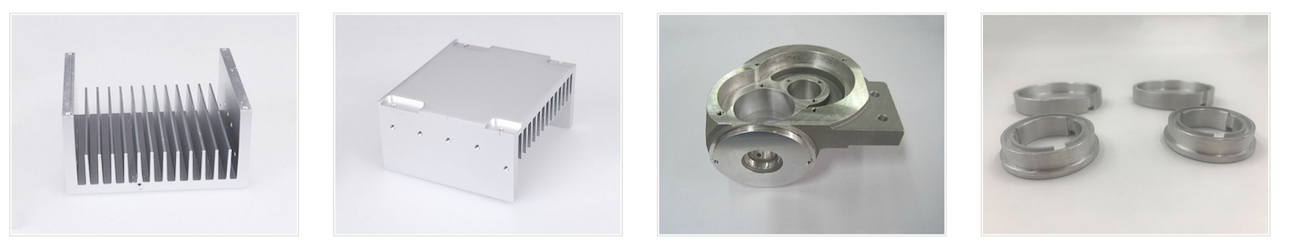

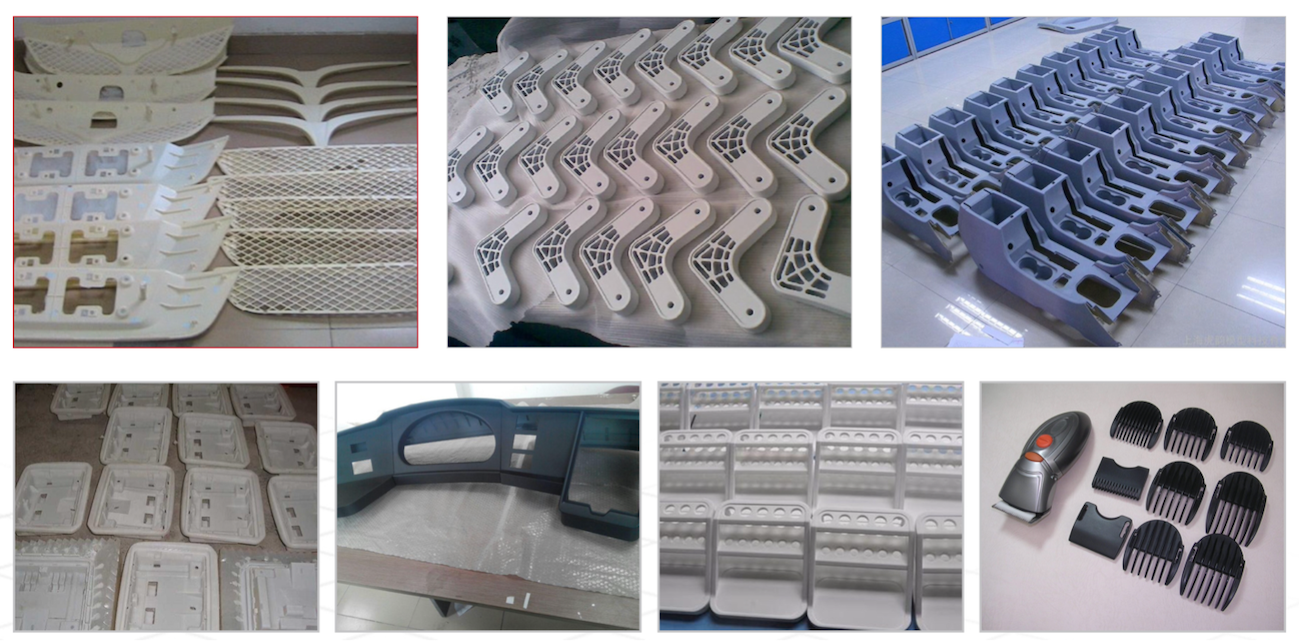

Prototypes can be divided into plastic prototypes and metal prototypes according to the materials used in the production:

1. Plastic prototype: It's raw material is mainly ABS or other flexible plastics, such as some popular but newly developed products in the market, such as functional telephones, display casings, game consoles, etc.

2. Metal prototype: its raw material is mainly aluminum-magnesium alloy or other, mainly used for some high-end prototypes, such as notebook computers, CD players, MP3, MP4 players and other home appliances.

3. Usually, some expensive products such as mobile phones and digital cameras need to make model machines before they are put on the market, that is, the so-called mobile phone model machines, camera model machines, etc. The mold processing is generally as follows: A. In the original mobile phone Keep the appearance unchanged on the basis of 3D drawings, and then modify the structure inside to the simplest structure that meets the customer's requirements. Structure B. According to the appearance of the real machine, use the simplest and mass-produced processes such as silk screen printing, oil injection, electroplating, etc. Imitate the appearance effect of the real machine, the simulation degree is above 80%. Some real machine effects such as metal wire drawing and IMD process are expensive, and are generally realized by common processes such as bronzing, silk screen mirror silver, etc., which can achieve the purpose of reducing costs. Mobile phone model machines, digital camera model machines, etc., if the customer has no special requirements for molds, ordinary materials such as 718 for cores can be used.

4. The necessity of prototype making;

A. Inspection of product appearance design and structural design

B. Avoid the risk of direct mold opening

C. The time to launch new products is greatly advanced

Welcome to contact us via enquiry@abcrapid.com to get more information !

Search

Recent Post