Riveting Processing

Riveting is a mechanical fastening process used to join materials using a rivet – a permanent mechanical fastener. This method has been used for centuries and remains relevant in many industries today.

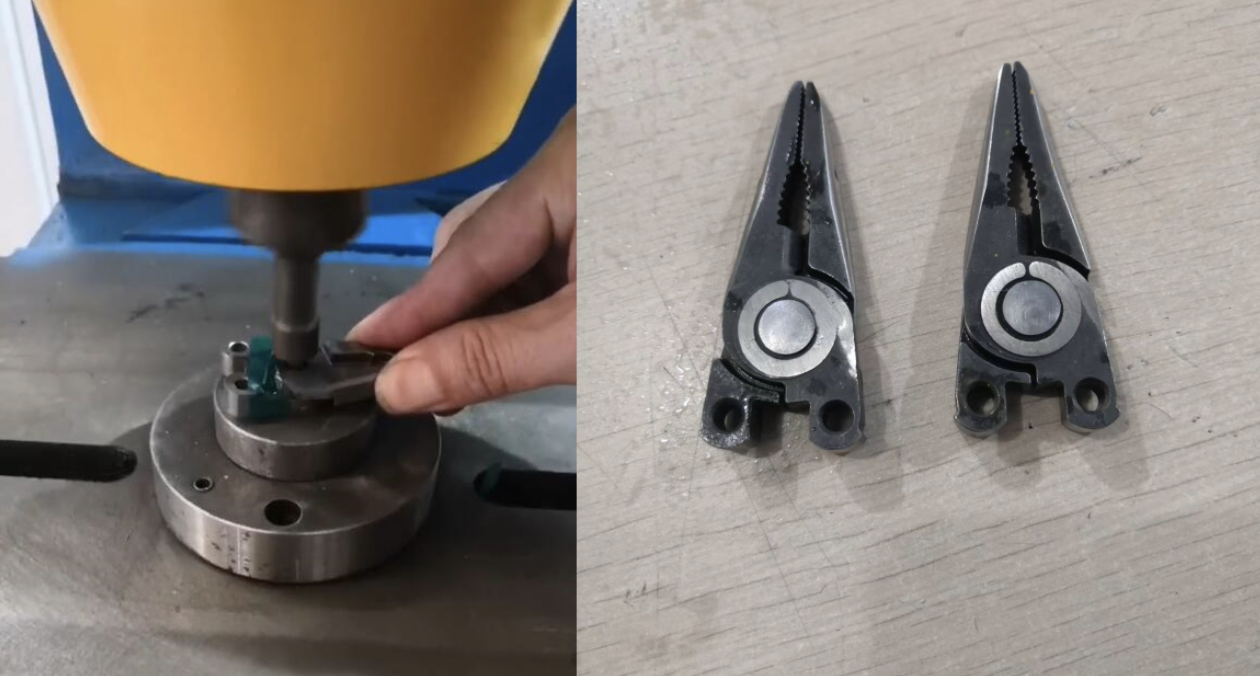

The Riveting Process

Riveting involves inserting a rivet through aligned holes in the materials to be joined. The tail of the rivet is then deformed, creating a second head that holds the materials together.

Types of Riveting

There are several types of riveting, including:

- Solid Riveting

- Blind Riveting (or Pop Riveting)

- Semi-tubular Riveting

- Full Tubular Riveting

Equipment

Riveting equipment is generally simpler than welding equipment. It may include:

- Rivet gun

- Hammer and bucking bar

- Drill

- Rivets

Skill Requirements

While riveting does require skill, it generally requires less training than welding. Many riveting tasks can be performed by workers with minimal specialized training.

Riveting Benefits

- Joining dissimilar materials: Riveting excels at joining materials that can’t be easily welded, such as certain combinations of metals or metal-to-metal joints.

- Lower equipment costs: Riveting generally requires less expensive and simpler equipment compared to welding setups.

- Ease of inspection: Riveted joints are typically easier to inspect visually, simplifying quality control processes.

- Lower skill requirements: Riveting often requires less specialized training than welding, potentially reducing labour costs.

- Preserves material properties: Unlike welding, riveting doesn’t involve heating materials to their melting point, which can help preserve the original properties of heat-treated or tempered materials.

If you have any prototyping project please feel free to contact: enquiry@abcrapid.com.

Search

Recent Post