SLA 3D Printing in China's Leading Vacuum Casting Factory

The Rise of SLA 3D Printing in China's Manufacturing Landscape

In recent years, China has emerged as a global manufacturing powerhouse, embracing cutting-edge technologies to stay ahead in the highly competitive market. Among these innovations, SLA 3D printing has taken center stage, revolutionizing the way prototypes are created. SLA, short for Stereolithography, is a high-precision 3D printing technique that utilizes resin-based materials to produce intricate and accurate models with exceptional surface finish. This technology has found its perfect partner in the vacuum casting process, together propelling China's manufacturing industry to new heights.

SLA 3D printing China impact on prototyping is truly revolutionary. It enables manufacturers to quickly and cost-effectively produce prototypes with intricate designs, allowing for rapid iterations and product improvements. The precision and speed ofSLA 3D printing service significantly reduce the development timeline, giving businesses a competitive edge in bringing their products to market faster than ever before.

Unveiling the Advantages of Vacuum Casting in China's Leading Factory

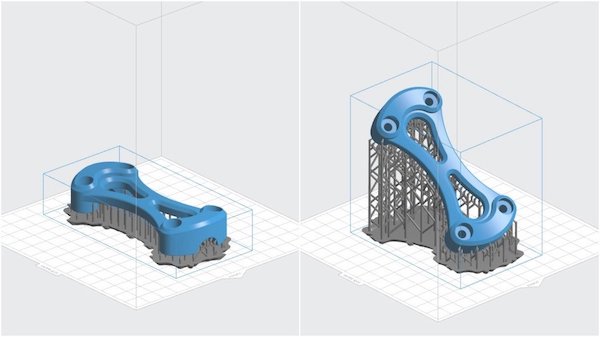

While SLA 3D printing service efficiently generates prototypes, vacuum casting is the ideal method for reproducing these models at scale. This technique involves creating silicone molds from the SLA-printed prototypes and then casting various materials into these molds to obtain multiple copies of the original design.

China's leading vacuum casting factory boast state-of-the-art equipment and expertise, making it a cost-effective solution for mass production. The versatility ofvacuum casting factory allows manufacturers to use a wide range of materials, such as polyurethane, to achieve the desired mechanical properties and appearance of the final product.

The combination of SLA 3D printing and vacuum casting opens up endless possibilities for businesses across various industries. From automotive to consumer electronics, medical devices to fashion, this powerful duo enables companies to transform their ideas into tangible products without breaking the bank.

Conclusion:

The synergy between SLA 3D printing and vacuum casting is driving innovation and propelling China's manufacturing industry to unprecedented heights. The marriage of precision prototyping through SLA technology with the cost-effective mass production capabilities of vacuum casting has transformed the product development landscape for businesses across the nation. As China continues to lead the way in adopting and advancing these technologies, we can expect even more remarkable advancements that will shape the future of manufacturing worldwide. So, if you're looking to turn your ideas into reality, look no further than China's SLA 3D printing and vacuum casting factories for an unparalleled experience in product development.

Search

Recent Post