What is the difference between CNC Machining Parts and Molds?

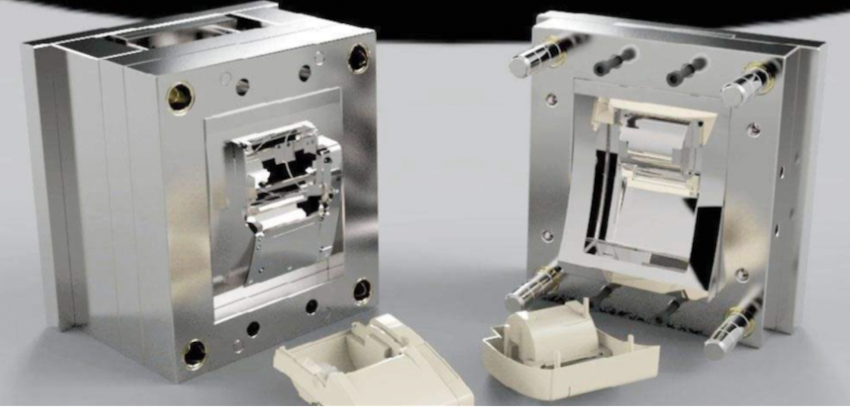

Generally, plastic rods are processed on machine tools or machining centers, or are made by hand in a form similar to casting, and cannot be mass-produced. Mold opening refers to processing the mold first, and then using the mold for injection molding or blow molding to mass-produce products. Generally, the shape is confirmed to the customer with the hand mold first, and then the mold is opened for mass production after confirmation.

The product data of CNC mold processing should be more accurate, the cost is relatively high, and the delivery time is long, which is suitable for mass production. The CNC-processed prototype can intuitively show the appearance design of the product; check the rationality of the structure and function; the reference of the mold design can avoid the risk of mold repair and modification; lead the market with CNC prototype models and shorten the development cycle; that is The data is slightly worse than the mold product.

Different tools: product processing is generally milling plane drilling and tapping, etc., mold is processing cavity copper work, etc.

Different programs: product processing programs are generally very simple, manual programming is generally sufficient, mold programs are very long, and computer programming is required

The transmission method is different: the product processing program is generally directly programmed manually on the side of the machine tool, and the mold program is programmed by a computer

The processing time is different: the processing time of the product is very short, and the processing time of the mold is very long, and some take a few days to process one.

Any question please feel free to contact by email: enquiry@abcrapid.com.

Search

Recent Post