What’s Precision Machining?

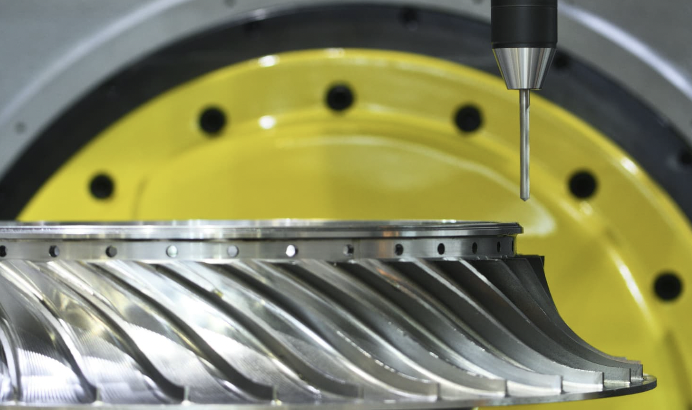

CNC Precision machining is a subtractive manufacturing process that utilizes high-speed CNC machines to create complex geometries with exceptional accuracy and within strict tolerances.

The idea is to create parts – precisely very close to the dimensions of the digital design. The tolerances are extremely low, ideally 1000th of an inch. This method employs state-of-the-art, CNC precision machines that get instructions from a computer system and recreate the same dimensions in the final part.

Precision Machining Process

Precision machining is a series of carefully planned steps that collectively produce a part perfectly matching its design.

1. Design Using CAD (Computer-Aided Design)

The process begins with a rough sketch of the part. Then, engineers use CAD software to create a graphical model, laying the foundation for the design. Popular CAD tools include AutoCAD and SolidWorks – the latter is famous for its robust 3D design capabilities.

2. Conversion to CAM (Computer Aided Manufacturing)

A CNC machine cannot directly interpret a graphical model; it requires machine-readable code. It came as a separate module but most modern CAD software now includes CAM capabilities.

With a single command, the software translates the 3D model into a series of code lines, comprising G-codes and M-codes. G-codes define the cutting tool paths and coordinates, while M-codes manage all auxiliary functions such as tool changes and coolant flow.

3. Material Selection and Preparation

The choice of material primarily depends on the part’s requirements, machinability, and cost. In most applications where hardness and strength are required, usually steel is the first choice. When weight is a concern, for instance in aerospace applications, manufacturers may choose lightweight aluminum. A subsequent section highlights this point in detail.

4. Setup of Precision Machinery

The machine setup includes selecting and precisely calibrating the precision machine tools, checking the fluid and coolant levels, and possibly running a dry run to ensure everything is set correctly.

5. Execution of Machining

Once everything is set up, the machining process can begin. During the process, monitor the initial stages of the process. Some machines may require a technician’s attention for adjustments, for instance, calibrating tool positions or modifying feed rates to accommodate variations in material hardness or tool wear.

6. Post-Processing Steps

Although precision machined parts often emerge from the machine close to their final form, some may require additional finishing, such as polishing or grinding. The last step is quality assurance checks to confirm that each part adheres to the specified precise dimensions.

If you have some parts to make, please feel free to contact us via enquiry@abcrapid.com to get fee quote.

Search

Recent Post