Which is better for metal parts, CNC or 3D printing?

Metal printing and CNC machining are two important technologies in the field of mechanical processing. They differ in design freedom, material utilization, and production volume. The specific analysis is as follows:

Design Freedom

Metal Printing: Metal printing can almost produce any complex geometric shape, including internal flow channels and lightweight structures, providing higher design flexibility.

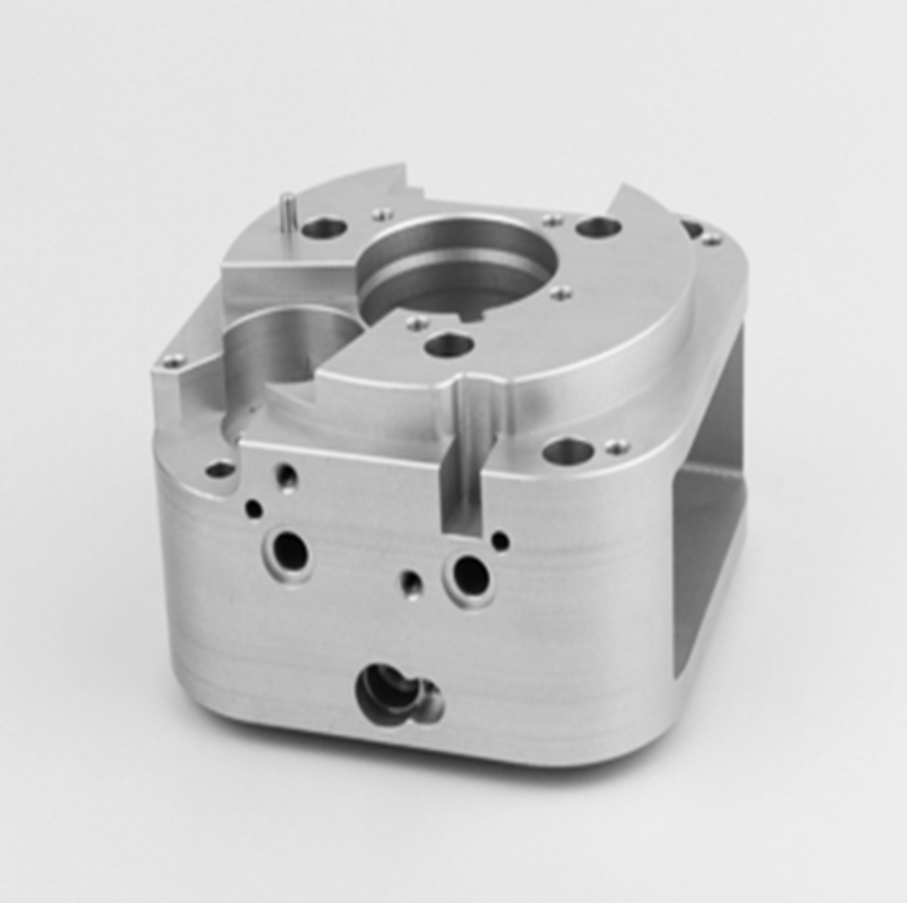

CNC Machining: CNC machining has limitations in processing certain complex shapes, especially those involving "complete angles" and internal right angles, which require special processes or tools to manufacture.

Material Utilization

Metal Printing: Metal printing uses an additive manufacturing process, resulting in less material waste and allowing materials to be added as needed.

CNC Machining: CNC machining generates more raw material waste during the processing, especially in the rough machining stage.

Production Volume

Metal Printing: Metal printing is more suitable for small-batch or complex design manufacturing. Its cost-effectiveness lies in reducing material waste and shortening the production cycle.

CNC Machining: CNC machining is more cost-effective in large-scale production, especially for simple or standardized parts.

Product Precision

Metal Printing: Metal printing may not achieve the same surface precision as CNC machining and usually requires post-processing to meet the required surface quality and tolerances.

CNC Machining: CNC machining can directly achieve high surface precision and strict tolerance requirements, eliminating some post-processing steps.

Material Selection

Metal Printing: Metal printing is initially limited by the types of available materials. Although more alloys and superalloys are becoming available for 3D printing, the selection range is still limited compared to traditional CNC machining.

CNC Machining: CNC machining uses a wider variety of materials, including but not limited to metals and plastics, offering greater flexibility in application.

Automation Degree

Metal Printing: The entire process of metal printing has a high degree of automation and requires little human intervention.

CNC Machining: Although CNC machining is operationally automated, the entire process requires professional technicians to monitor to ensure technical safety and processing quality. production cycle

Metal printing: Metal printing offers a faster production cycle for the manufacturing of complex components, especially in prototyping and customized designs.

CNC machining: CNC machining is faster for simple parts or those with existing CNC programs, particularly in batch production. cost

Metal printing: Metal printing equipment and materials are relatively expensive, but with technological advancements, it is expected that costs will decrease in the future.

CNC machining: CNC machining requires a high initial investment in equipment, but its operating costs are relatively low, especially in large-scale production.

Based on the above analysis, the following suggestions are proposed:

When considering small-batch, highly personalized designs, metal printing shows its advantages.

CNC machining is more suitable for applications that require large-scale production and precise tolerances.

Combining the use of these two technologies can leverage their respective strengths, such as using metal printing to create complex prototypes and then CNC for finishing to achieve high precision requirements.

Overall, metal printing has obvious advantages in design freedom and material utilization, especially for complex and personalized design needs. CNC machining, on the other hand, excels in precision, material selection, and large-scale production, particularly when the production scale is large, as it offers higher cost efficiency. Both technologies have their own merits, and the best approach might be to combine their use to fully capitalize on their advantages.

If you have project in hard, please feel free to contact: enquiry@abcrapid.com.

Search

Recent Post