Why Does The Hand Model Need Subsequent Polishing ?

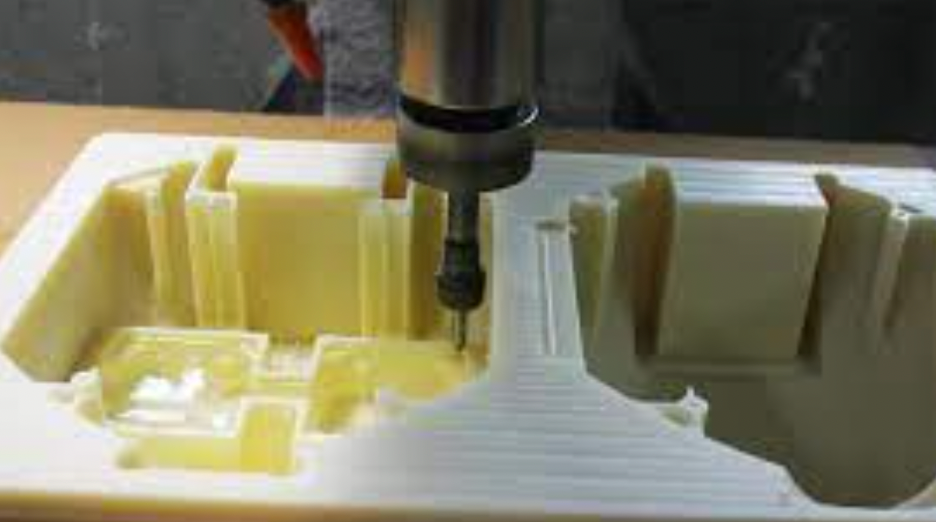

There are many techniques for prototypes, such as 3D printing, CNC machining, sheet metal and vacuum casting. , one of the important links is grinding. For example, after CNC machining, the surface of a part will contain a lot of burrs and tool marks. Therefore, manual processing is required. Generally speaking, there are two main methods of sanding: mechanical sanding and dry sanding.

Mechanical grinding: For large-scale construction, in order to improve work efficiency, mechanical grinding methods such as electric grinding machines (disc type, vibration type) can be used.

When dry sanding, it needs to be roughly sanded with coarse sandpaper, then the surface rough edges are removed, and then sanded carefully. After a polishing is completed, you can encounter atomic ash and enlarge the roughness of the product surface, so that you can observe the defects with your eyes and correct the existing defects until a product completes all the polishing processes.

The function of grinding the hand model:

1. Enhance the adhesion of the coating: Before spraying the new paint film, the old paint film after drying is usually polished, so there will be phenomena such as smooth surface transition and poor adhesion. Therefore, the mechanical adhesion of the coating can be enhanced after sanding.

2. Substrate: For the substrate, it is mainly to remove burrs, oil stains and dust on the surface of the substrate.

3. Putty surface: Generally, the surface is relatively rough, and it needs sanding to get a relatively flat surface, so sanding can reduce the roughness of the workpiece surface.

Welcome to contact us via enquiry@abcrapid.com to get more information !

Search

Recent Post